One of the most promising applications of Ultra High Performance Concrete is in bridge construction, where its superior performance can be utilized to design lightweight, durable, and aesthetically pleasing structures that require minimal maintenance and have extended service lives. Examples of UHPC being successfully used in bridge projects can be found around the world, such as Mars Hill Bridge, first bridge of United States constructed using UHPC. These projects demonstrate the potential of UHPC to reduce material usage, simplify construction processes, and enhance the overall sustainability of our transportation infrastructure.

In the field of building construction, Ultra High Performance Concrete offers numerous advantages, including the ability to design slender and architecturally striking structures that can withstand extreme loads and environmental conditions. Ultra High Performance Concrete’s enhanced strength and stiffness can also enable the construction of taller and more slender buildings, potentially revolutionizing the way we design and build high-rise structures. Furthermore, the excellent seismic performance of Ultra High Performance Concrete has been recognized as a valuable characteristic in regions prone to earthquakes, providing enhanced safety and resilience for occupants and infrastructure.

Ultra High Performance Concrete additionally offers considerable potential for the restoration, retrofitting, and fortification of current structures, providing a robust and enduring approach to prolong the lifespan of our deteriorating infrastructure. Its exceptional adhesive properties, resilience against environmental harm, and compatibility with traditional concrete materials render Ultra High Performance Concrete an optimal choice for such purposes.

Despite the numerous advantages offered by Ultra High Performance Concrete, some challenges remain, including the higher initial material and production costs associated with this advanced concrete technology. However, ongoing research and development efforts are focused on optimizing the material formulations, manufacturing techniques, and structural design approaches to minimize these costs and make UHPC a more economically viable option for a wider range of applications.

1. Ultra High Performance Concrete in Bridge Construction

Utilizing Ultra High Performance Concrete in the building of bridges has gained considerable interest because of its extraordinary mechanical characteristics, which can improve the efficiency and lifespan of such structures. In this section, the application of Ultra High Performance Concrete in bridge deck systems, girders, and other components are discussed to demonstrate its potential for improving bridge design and longevity.

1.1 Bridge Deck Systems

Ultra High Performance Concrete’s high compressive strength, tensile strength, and durability make it an ideal material for bridge deck systems. Conventional bridge decks are often subject to deterioration due to chloride penetration, freeze-thaw cycles, and fatigue, which can reduce the service life of the structure and hence the maintenance cost will increase. The use of Ultra High Performance Concrete in bridge deck systems can mitigate these issues by providing increased resistance to these factors.

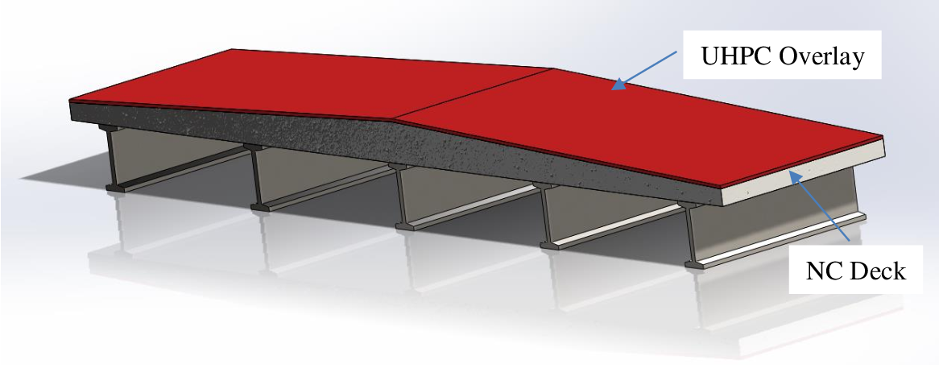

One notable example of UHPC’s application in bridge deck systems is its use as an overlay material, as shown in Figure-5. By applying a thin layer of UHPC on top of an existing or new bridge deck, the deck’s durability and resistance to environmental factors can be significantly improved. This can lead to a reduction in maintenance costs and an extension of the bridge’s service life.

Additionally, Ultra High Performance Concrete can be used in the construction of prefabricated bridge deck panels, which offer several advantages over conventional cast-in-place concrete. UHPC’s remarkable strength and ability to deform (i.e., ductility) allow for the creation of thinner, lighter panels that can be more easily transported and installed on-site, reducing construction time and costs.

1.2 Bridge Girders

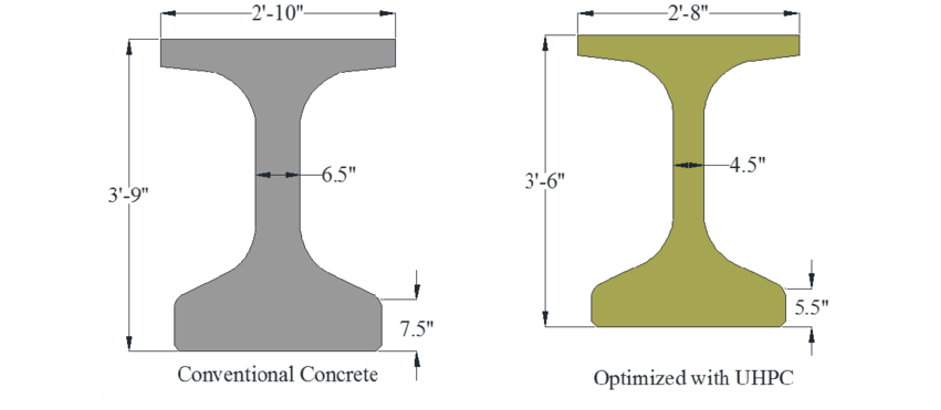

UHPC’s exceptional mechanical properties make it well-suited for use in bridge girders, which are critical structural components that support the bridge deck and transfer loads to the substructure. UHPC’s higher tensile and compressive strength allows for the design of more slender girders (as shown in Figure-6), resulting in reduced material usage and more efficient structural systems.

One notable application of Ultra High Performance Concrete in bridge girder design is the development of UHPC-prestressed girders. These girders utilize UHPC’s high strength and ductility in combination with prestressing techniques to achieve an even greater load-bearing capacity and resistance to cracking. This can lead to more efficient and durable bridge structures with extended service lives.

Moreover, the use of Ultra High Performance Concrete in the construction of composite girders, in which steel and concrete elements are combined, can provide additional benefits. The strong bond between Ultra High Performance Concrete and steel elements can result in more efficient load transfer between the two materials, enhancing the overall performance of the composite girder.

1.3 Other Bridge Components

In addition to bridge decks and girders, Ultra High Performance Concrete can also be utilized in various other bridge components to improve their performance and durability. Some examples include:

Bridge Joints: Ultra High Performance Concrete can serve as a bonding substance for precast concrete components, offering a robust, long-lasting link with minimal reinforcing. Employing UHPC in bridge connections can lead to enhanced and sturdy bridge frameworks with reduced maintenance requirements.

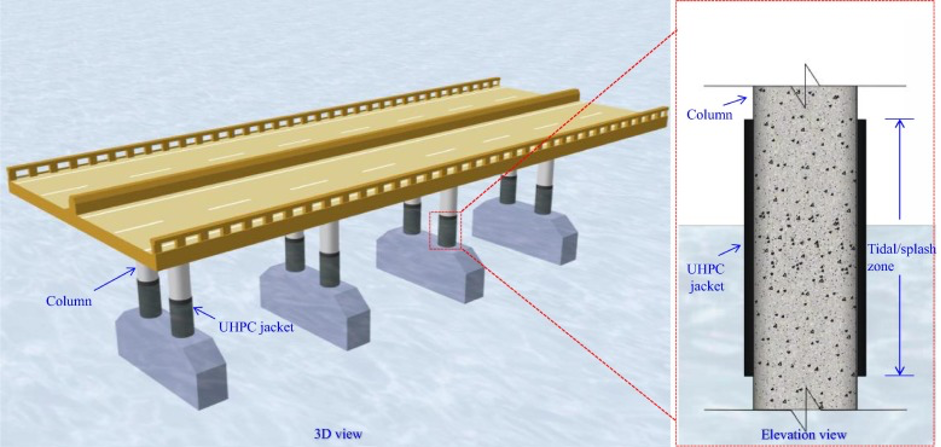

Bridge Piers and Abutments: Ultra High Performance Concrete’s durability and the strength (specially in compression) make it an excellent choice for the construction of bridge piers and abutments, which are critical components in transferring loads from the superstructure to the foundation. The use of UHPC in these components can result in more efficient and durable structures with extended service lives and reduced maintenance costs.

Bridge Bearings and Expansion Joints: The high strength and ductility of Ultra High Performance Concrete can also be utilized in the design of bridge bearings and expansion joints, which are essential for accommodating thermal and dynamic movements in bridge structures. The use of UHPC in these components can improve their performance and durability, leading to more resilient and long-lasting bridges.

Reinforcement and Strengthening Applications: Ultra High Performance Concrete can be used in conjunction with conventional reinforcement materials or advanced composites, such as carbon fiber-reinforced polymers (CFRP), to provide additional strengthening and reinforcement to existing bridge structures. This can be particularly beneficial for structures subjected to increased loads or exhibiting signs of deterioration.

2. Ultra High Performance Concrete in Building Construction

Ultra High Performance Concrete offers numerous advantages over conventional concrete, making it a promising material for use in various building construction applications. Its high strength, ductility, and durability make it particularly suitable for high-rise buildings, seismic-resistant structures, and other demanding applications. In this section, the potential of UHPC in building construction is discussed, with a focus on above mentioned specific areas.

2.1 High Rise Buildings

Tall structures pose distinct obstacles concerning structural planning, material necessities, and building methodologies. UHPC’s remarkable mechanical attributes, like elevated compressive and tensile power, can considerably aid in the development and creation of more effective and long-lasting towering edifices.

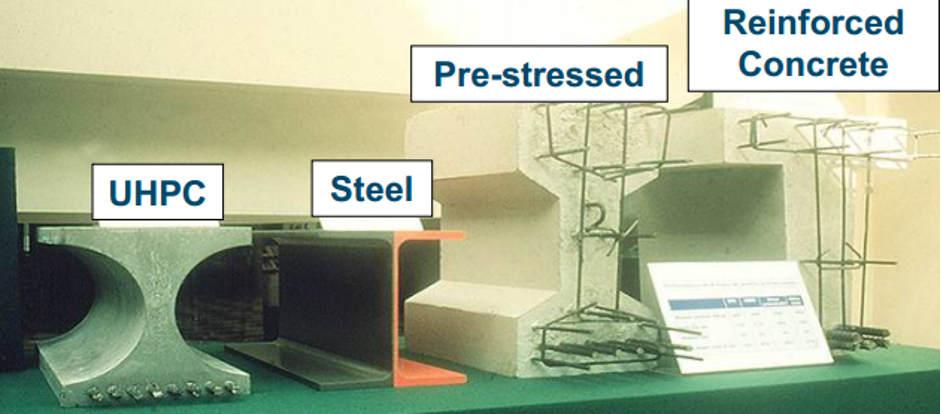

Reduced Material Usage: Higher strength of UHPC allows for the reduction in the weight of structural elements, such as columns, beams, and walls, resulting in reduced material usage and lighter structures, as shown in Figure-7. This can lead to more cost-effective and sustainable high-rise buildings.

Improved Structural Performance: UHPC’s high ductility and post-cracking behavior can enhance the overall structural performance of high-rise buildings, particularly in terms of load-carrying capacity, deformation capacity, and resistance to progressive collapse.

Enhanced Durability: UHPC’s enhanced durability, in terms of its resistance to chemical attack, freeze-thaw cycles, and abrasion, can contribute to the extended service life of high-rise buildings, reducing maintenance costs and improving overall sustainability.

2.2 Seismic-Resistant Structures

Seismic-resistant structures are designed to withstand the forces generated by earthquakes, ensuring the safety and functionality of buildings during and after such events. UHPC’s unique mechanical properties make it a promising material for the construction of seismic-resistant structures:

Ductility and Energy Dissipation: The high ductility of UHPC allows it to undergo large deformations without failure, enabling it to dissipate seismic energy more effectively than conventional concrete. This can result in structures that are more resilient to seismic forces and exhibit improved performance during and after earthquakes.

Crack Resistance and Self-Centering Capability: UHPC’s post-cracking performance, characterized by multiple microcracks and fiber bridging, can significantly improve its resistance to cracking under seismic loading. Furthermore, UHPC’s self-centering capability, which refers to its ability to return to its original shape after deformation, can contribute to the structural stability of seismic-resistant structures.

Strengthening and Retrofitting: Ultra-High-Performance Concrete” can be combined with cutting-edge composite substances, like carbon fiber-reinforced plastics (CFRP), to fortify and refurbish current structures, enhancing their resistance to earthquakes. This can be especially advantageous for edifices situated in earthquake-prone areas or those that were not initially planned for seismic resilience.

2.3 Other Demanding Applications

In addition to high-rise buildings and seismic-resistant structures, UHPC can also be utilized in various other demanding building construction applications:

Blast-Resistant Structures: UHPC’s strength and longer durability can prove advantageous when creating blast-resistant buildings, designed to safeguard occupants and essential infrastructure from the repercussions of detonations. The use of UHPC in these structures can result in improved resistance to blast loading, reduced damage, and enhanced structural integrity during and after blast events.

Fire-Resistant Structures: Although concrete is generally considered to have good fire resistance, UHPC’s increased density and reduced porosity can further improve its fire resistance properties. The use of UHPC in building construction can contribute to enhanced fire resistance and reduced structural damage in the event of a fire.

Energy-Efficient Buildings: The thermal properties of UHPC, such as its low thermal conductivity, can contribute to the energy efficiency of buildings by reducing heat transfer through structural elements. This can result in lower energy consumption for heating and cooling, contributing to more sustainable and environmentally friendly building designs.

Architectural Applications: The unique aesthetic and design (as shown in Figure-8) possibilities offered by UHPC, including its ability to be cast into complex shapes and thin, lightweight panels, can enable architects to create innovative and visually striking building designs. UHPC can be used in façades, cladding, and other architectural elements to achieve both functional and aesthetic objectives.

3. Repair and Rehabilitation with Ultra High Performance Concrete

The repair, rehabilitation, and strengthening of existing structures are essential for maintaining their functionality, safety, and longevity. UHPC has captured interest as a potent material for such applications, owing to its distinct mechanical characteristics and longevity. In this section, the effectiveness of UHPC in the repair and retrofitting of existing structures and its potential for extending their service life are discussed.

3.1 UHPC for Repair and Rehabilitation

Bonding and Compatibility: One of the critical factors to consider when using UHPC for repair and rehabilitation is the bonding and compatibility between the existing concrete and the UHPC overlay or patch. Research has shown that UHPC exhibits excellent bonding characteristics, ensuring a strong and durable connection between the repair material and the existing concrete substrate. This can result in effective and long-lasting repairs, contributing to the overall structural integrity and service life extension.

Crack Repair and Sealing: UHPC’s high compressive and tensile strength, as well as its post-cracking behavior, make it suitable for repairing and sealing cracks in existing concrete structures. The use of UHPC for crack repair can help prevent further deterioration and damage caused by moisture ingress, freeze-thaw cycles, and other environmental factors, ultimately extending the lifespan of the buildings, bridges, etc.

Structural Strengthening: UHPC can be employed to reinforce structural components, like beams, columns, and slabs, by adding it as a covering, casing, or supplementary stratum (illustrated in Figure-9). The exceptional strength and flexibility of UHPC can substantially enhance the load-bearing capability, bending capacity, and overall structural efficiency of the refurbished elements, aiding in prolonging the structure’s service life.

3.2 Retrofitting with UHPC

Seismic Retrofitting: UHPC can be combined with cutting-edge composite materials, like carbon fiber-reinforced polymers, to enhance the earthquake resistance of existing structures through seismic retrofitting. By using UHPC in a range of retrofitting methods, including column jacketing, beam fortification, and wall reinforcement, structural capabilities of the modified structures can be substantially improved, resulting in greater resistance to seismic activity.

Blast and Impact Retrofitting: The high strength and ductility of UHPC make it an effective material for retrofitting structures to improve their resistance to blast and impact loading. The use of UHPC in combination with other materials and techniques, such as steel reinforcement and advanced composites, can result in more robust and resilient structures that are better equipped to withstand the effects of explosions and other impact-related events.

Fire Retrofitting: The superior fire resistance properties of UHPC, stemming from its increased density and reduced porosity, can be utilized in retrofitting existing structures to improve their fire performance. By applying UHPC as a protective layer or incorporating it into the structural elements, buildings can achieve enhanced fire resistance, contributing to improved safety and reduced structural damage in the event of a fire.

4. 15 Applications of Ultra High Performance Concrete

The various applications of Ultra-High Performance Concrete (UHPC) in different fields of civil engineering are discussed below:

| Field of Civil Engineering | Application of UHPC | Real-Life Structures |

|---|---|---|

| Bridge Construction | Used in critical bridge components for superior strength and durability | Mars Hill Bridge, Iowa, USA |

| Building Construction | Used for constructing slim, high-strength building structures | 18 Robinson, a commercial skyscraper in Singapore |

| Road and Pavement Construction | Used in heavy-duty pavements and roads for enhanced lifespan | Experimental sections of the A4 motorway, France |

| Seismic Design | Used in structures for enhanced seismic resistance | Shake table testing of UHPC frames, University of Nevada |

| Offshore and Marine Structures | Used for superior resistance against aggressive marine environment | PLEM (Pipeline End Manifold) for the TOTAL company, Congo |

| Architectural Applications | Used for creating complex shapes and innovative designs | Ruyi Bridge in Shenzen, China |

| Repair and Retrofitting | Used in repairing and strengthening existing structures | Rehabilitation of the Interstate 90 George V. Voinovich Bridge, Ohio, USA |

| Precast Elements | Used for creating high-strength, durable precast components | Precast pedestrian bridge in Sherbrooke, Canada |

| Railway Infrastructure | Used for constructing durable railway sleepers and platforms | Railway sleepers for a heavy haul line, Saudi Arabia |

| Wind Energy Structures | Used for constructing durable and high-strength wind turbine towers | Prototype wind turbine tower, Germany |

| Security and Defense Structures | Used for enhanced impact resistance in security and defense structures | Protective blast wall at the U.S. Embassy in London. |

| Waste Management Structures | Used for construction of waste storage containers and structures | Nuclear waste storage containers developed by Orano (formerly AREVA), a French multinational group. |

| Water and Wastewater Structures | Used for enhanced resistance against aggressive chemicals | Water treatment plant in St. John’s, Newfoundland, Canada |

| Airport Infrastructure | Used for constructing durable airport pavements and structures | Dallas/Fort Worth International Airport |

| Tunneling and Underground Structures | Used for enhanced resistance against aggressive underground conditions | Ejpovice Tunnel in the Czech Republic |

FAQ’s

What is Ultra-High Performance Concrete (UHPC)?

Ultra-High Performance Concrete (UHPC) is a unique type of concrete known for its superior strength, durability, and other beneficial properties. It is significantly stronger than conventional concrete and has improved resistance to weathering, leading to its increased use in various structural applications.

How is UHPC used in bridge construction?

UHPC’s exceptional strength and durability make it ideal for bridge construction. It is used in critical components like the deck, girders, and joints to enhance the bridge’s resilience, extend its lifespan, and reduce maintenance needs.

How does UHPC contribute to building construction?

UHPC enables the creation of slimmer, more elegant structures without compromising strength. Its high compressive and tensile strengths allow for thinner walls, lighter panels, and a reduction in the overall amount of concrete required, which can lead to significant cost savings.

What role does UHPC play in repair and rehabilitation?

UHPC is often used in repair and retrofitting of existing structures due to its excellent bond strength and durability. It can help improve structural integrity, enhance load-carrying capacity, and increase the service life of the rehabilitated structures.

What are the environmental implications of using UHPC?

Although the production of UHPC requires more energy compared to traditional concrete, its superior performance and longer lifespan can offset the higher initial environmental impact. Its increased lifespan reduces the need for frequent replacements, which contributes to sustainability.

How does UHPC enhance the durability of structures?

UHPC has remarkable resistance to environmental and mechanical stresses, such as freezing and thawing, chemical attack, abrasion, and even fire, enhancing the durability of structures and reducing the need for maintenance and repairs.

Can UHPC be used in residential construction?

Yes, UHPC can be used in residential construction, providing benefits like enhanced durability, improved aesthetics, and potential cost savings due to its long lifespan and low maintenance requirements.

What are the cost implications of using UHPC?

Although UHPC is more expensive than conventional concrete, its improved durability and longer lifespan can lead to lower lifecycle costs by reducing the frequency of repair and replacement.

How does UHPC contribute to architectural design?

The high strength and moldability of UHPC allow for the creation of complex shapes and thinner, more lightweight structures, providing architects with greater design flexibility and aesthetic possibilities.

What is the future of UHPC in construction?

The future of UHPC in construction is promising. Its exceptional properties open up possibilities for innovative designs and more sustainable, durable constructions, potentially transforming the landscape of the construction industry.

Read More