In structural engineering, strength reduction factors, also known as resistance factors, play a critical role in the design and analysis of structures. As crucial elements in the strength design method, or Load and Resistance Factor Design (LRFD), these factors help ensure that structures are both safe and efficient. This article aims to delve into the purpose of strength reduction factors and explain why they are smaller for columns than for beams.

1. Strength Reduction Factors

Strength reduction factors, denoted as φ (Phi), are utilized in the strength design method to incorporate an element of safety into the design process. They are applied to the nominal strength of a structural element, reducing it to a design strength that can safely resist the expected load effects.

The primary purpose of strength reduction factors is to account for the uncertainties and variabilities associated with material properties, manufacturing processes, workmanship quality, and the actual applied loads on a structure. By doing so, they provide a buffer for unexpected circumstances or inaccuracies, ensuring that structures have an appropriate margin of safety and reliability.

2. Role of Strength Reduction Factors in the Strength Design Method

In the Strength Design Method or LRFD approach, both loads and material strengths are considered probabilistic, acknowledging the inherent uncertainties. The method involves calculating the structure’s ultimate strength under maximum load conditions and applying the strength reduction factors to these calculated strengths.

Using the strength reduction factor in the calculation of design strength is crucial as it helps balance the probabilities of exceeding the expected load and the material’s resistance capacity. This balance is necessary to maintain a uniform level of safety in the design of structures.

3. Variability of Strength Reduction Factors

It’s important to note that strength reduction factors are not uniform across all materials and structural elements. They vary based on the type of material, the type of failure mode, and the specific structural element under consideration (e.g., columns or beams). This variability is a reflection of the different levels of uncertainty or risk associated with different elements or failure modes.

4. Why are Strength Reduction Factors Smaller for Columns than for Beams?

Columns and beams are two fundamental elements in structures, but they perform different roles and respond differently under load. Beams are primarily designed to resist bending, while columns are designed to resist compression. Consequently, their failure modes differ significantly, and so does the risk associated with these failures.

4.1 The Risk and Consequences of Failure

The consequences of a column failure are generally more severe than that of a beam. If a column fails, it can lead to a progressive collapse of the entire structure, while a beam failure might only affect a part of the structure. Given the higher risk associated with column failure, a smaller strength reduction factor is applied to columns compared to beams to provide a greater margin of safety.

4.2 Load Path and Buckling Considerations

Columns also have a direct role in transferring loads from the structure to the foundation. Thus, any compromise in their strength could lead to a destabilization of the entire load path. Furthermore, columns are more susceptible to buckling, a failure mode that can occur suddenly and without much warning. The smaller strength reduction factors for columns account for these considerations, further enhancing the structure’s safety.

4.3 Variability Reflecting Different Structural Elements

The differing values of strength reduction factors for various structural components reflect the distinct roles they play in a structure. This variability allows engineers to design each component to effectively handle its individual load and performance requirements, while still ensuring overall structural integrity.

4.4 Impact of Failure Modes

Columns and beams exhibit different behaviors under stress and hence, fail differently. Columns are susceptible to buckling under compressive loads and can fail suddenly. Beams, on the other hand, typically fail due to bending or shear stress. These failure modes are more gradual and provide noticeable signs before failure. This difference in failure modes and their potential consequences is another reason why columns are assigned smaller strength reduction factors than beams.

4.5 Diverse Material Behavior

Material behavior is another factor that influences the value of the strength reduction factor. For instance, concrete, widely used in columns and beams, exhibits different behaviors under tension and compression. The smaller strength reduction factor for columns acknowledges these diverse behaviors, adding an extra level of safety to the design process.

4.6 Safety and Reliability of Structures

Ultimately, the primary purpose of strength reduction factors, regardless of the specific value used, is to ensure the safety and reliability of the structure. By providing a margin of safety that accounts for uncertainties and variability in both material properties and load effects, these factors help prevent catastrophic structural failures.

4.7 Importance in Modern Design

In modern structural design, understanding the role and purpose of strength reduction factors is essential. They are a critical component of the strength design method, which has gained widespread acceptance in the civil engineering community due to its reliability and efficiency. By accurately using strength reduction factors, engineers can design structures that are not only safe and reliable but also efficient and economical.

5. Strength Reduction Factors for Columns and beams as per ACI 318

The American Concrete Institute’s ACI 318 standard, “Building Code Requirements for Structural Concrete,” provides values for strength reduction factors (also known as φ-factors or resistance factors). These are crucial for the design of concrete structures, including columns and beams, using the Load and Resistance Factor Design (LRFD) or strength design method.

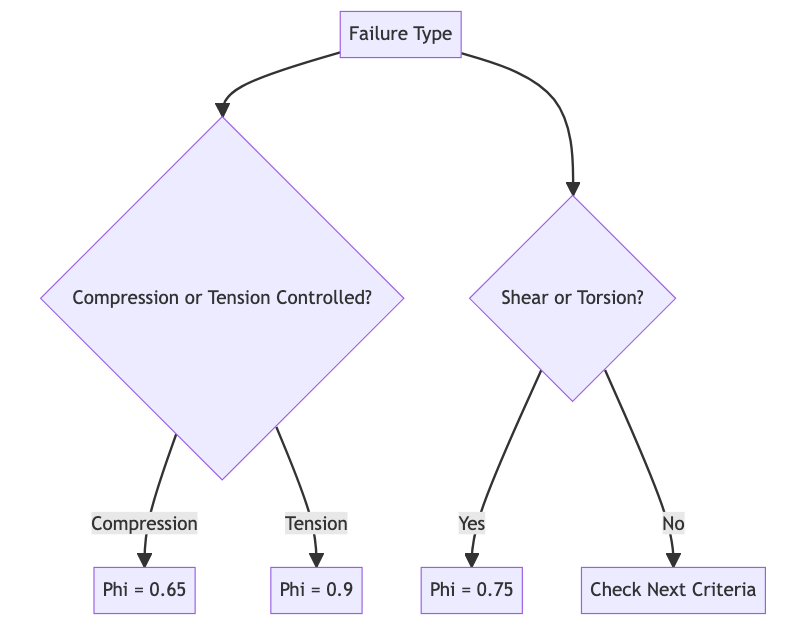

Here are the φ-factor values for different types of failure as per the ACI 318-19:

The American Concrete Institute’s ACI 318 standard, “Building Code Requirements for Structural Concrete,” provides a list of strength reduction factors (also known as φ-factors or resistance factors) for different types of failures in concrete structures. Here are the φ-factor values from the ACI 318-19:

- For Flexural and Axial Compression:

- Beams, slabs, and footings (φ = 0.9)

- Spiral-reinforced columns (φ = 0.75)

- Tied columns (φ = 0.65)

- For Compression Controlled Sections:

- All structures (φ = 0.65)

- For Tension-Controlled Sections:

- All structures (φ = 0.9)

- For Shear and Torsion:

- All structures (φ = 0.75)

- For Bearing on Concrete:

- All structures (φ = 0.70)

- For Anchorage in Tension of Steel Reinforcement, Anchorages, Inserts, and Connections:

- Cast-in headed bolts and headed stud (φ = 0.75)

- Post-installed anchors and reinforced concrete (φ = 0.65)

- For Anchorage in Shear of Steel Reinforcement, Anchorages, Inserts, and Connections:

- Cast-in headed bolts and headed stud (φ = 0.65)

- Post-installed anchors and reinforced concrete (φ = 0.60)

- For Spirally Reinforced or Tied Circular Sections:

- Flexure only (φ = 0.75)

- Axial load and flexure (φ = 0.70)

- For Slenderness Effects:

- All structures (φ = 0.80)

FAQ’s

What are strength reduction factors in structural engineering?

Strength reduction factors, or resistance factors, are crucial elements in structural engineering used in the Strength Design Method or Load and Resistance Factor Design (LRFD). These factors reduce the nominal strength of a structural component to a design strength, which can safely resist the expected load effects. They account for the uncertainties and variabilities in material properties, manufacturing processes, workmanship, and load effects.

Why are strength reduction factors important in structural design?

Strength reduction factors incorporate a margin of safety into the design of structures, compensating for uncertainties in material properties, workmanship quality, and actual applied loads. They ensure that structures have an appropriate level of safety and reliability, preventing catastrophic failures.

Are strength reduction factors the same for all structural elements?

No, strength reduction factors vary based on the type of material, type of failure mode, and specific structural element (like columns or beams). This variability reflects different levels of uncertainty or risk associated with different elements or failure modes.

Why are strength reduction factors smaller for columns than for beams?

The strength reduction factors are smaller for columns due to the severe consequences of column failure, which can potentially lead to the collapse of the entire structure. Columns are also more susceptible to sudden buckling, have a direct role in transferring loads, and require a greater margin of safety, hence the smaller strength reduction factors.

How do strength reduction factors contribute to the safety of structures?

Strength reduction factors contribute to structural safety by providing a margin that accounts for uncertainties in both material properties and load effects. By reducing the nominal strength of a structural element to a safe design strength, they help prevent unexpected failures and ensure overall structural integrity.

What role do strength reduction factors play in the strength design method or LRFD?

In the Strength Design Method, strength reduction factors are applied to the calculated maximum strength of a structure under load. They help balance the probabilities of exceeding the expected load and the material’s resistance capacity, ensuring a uniform level of safety in structural design.

How do strength reduction factors affect the economic efficiency of structures?

Strength reduction factors help create designs that are not only safe and reliable but also efficient. By providing a more accurate reflection of the material’s behavior and the load effects, they allow for an optimal use of materials, leading to economic efficiency.

Are strength reduction factors used in the allowable stress design method?

No, strength reduction factors are specific to the Strength Design Method or LRFD. They are not used in the Allowable Stress Design method, which uses a single safety factor applied to the allowable stress of the material.

What influences the value of strength reduction factors?

Several factors influence the value of strength reduction factors, including the type of material, type of failure mode, and the specific structural element. Each of these factors brings a different level of uncertainty or risk, which is accounted for in the strength reduction factor.

How do the failure modes of columns and beams impact the strength reduction factors?

Columns and beams have different failure modes which impact the value of their strength reduction factors. Columns, which are susceptible to sudden buckling under compressive loads, have a smaller strength reduction factor to account for this risk. Beams typically fail due to bending or shear stress, which are more gradual failure modes, hence they have larger strength reduction factors.

Read More