A lintel is a structural horizontal support used to span an opening in a wall or between two vertical supports. It is often found over portals, doors, windows, and fireplaces. Simply put, it’s the bridge that carries the load from above to the pillars on either side.

Lintels are paramount in construction for a variety of reasons. The first and foremost is that they bear and distribute the load that comes from the structure above, ensuring stability. This redistribution of weight allows for doors and windows to exist without the threat of a building collapsing.

Additionally, lintels can also serve an aesthetic purpose, offering a pleasing architectural framing to openings within a structure. Therefore, they combine the duality of purpose – structural necessity and design enhancement. In this article, we are discussing the various types of Lintels and their uses.

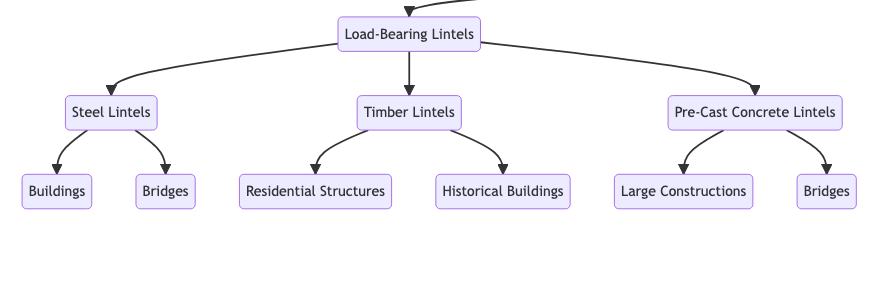

1. Load-Bearing Lintels

Load-bearing lintels, as their name suggests, are designed to carry and distribute the weight from the structure above them. They serve as a crucial element in construction, responsible for the stability of the openings they span. By effectively handling this load, they allow for the creation of various architectural features like doors, windows, and archways.

There are many advantages to using load-bearing lintels. Firstly, they provide the essential service of supporting the masonry above the aperture, preventing potential collapse. Secondly, they help distribute the weight evenly across the structure, reducing stress on specific points. Furthermore, they can also help to prevent cracking, buckling, or bowing of the structure over time.

There are several types of lintels (load bearing), each offering different strengths and benefits. These include pre-cast concrete lintels, steel lintels, and timber lintels.

1.1 Pre-cast Concrete Lintels

Pre-cast concrete lintels are created off-site, cured, and then transported for installation. One of the main advantages of using pre-cast concrete lintels is their uniformity and quality control. Due to their manufacturing process, they are constructed under controlled conditions, ensuring a consistent, high-quality product.

Moreover, pre-cast concrete lintels are highly durable and resistant to fire, providing a safer option for construction. They also offer excellent load-bearing capacity, which is necessary for structures with heavy loads. They are cost-effective and relatively easy to install, saving both time and labor.

1.2 Steel Lintels

Steel lintels are another popular choice in construction. They are incredibly strong and offer excellent load-bearing capacity. One of the main advantages of using steel lintels is their flexibility in design. They can be easily fabricated into various shapes and sizes, allowing for more architectural freedom.

Furthermore, steel lintels are highly durable and have a long lifespan. They are also resistant to pests and fire, making them a safe choice. They are ideal for structures with heavy loads, and due to their slim profile, they can be less obtrusive in a building’s design.

1.3 Timber Lintels

Finally, we have timber lintels. These are typically used in traditional and heritage buildings due to their aesthetic appeal. They blend well with the natural environment and add a warm, rustic charm to the structure.

Timber lintels, while not as strong as their steel or concrete counterparts, still provide ample load-bearing capacity for most residential buildings. They also have the benefit of being a renewable resource, which is an increasingly important consideration in today’s construction industry.

Furthermore, timber lintels are easy to work with. They can be cut, shaped, and drilled onsite, allowing for greater flexibility and customization. However, it should be noted that they require regular maintenance to prevent rot and insect damage.

2. Non-Load Bearing Lintels

Non-load-bearing lintels, often found in interior design and partition walls, primarily serve aesthetic and design functions. Unlike load-bearing lintels, they don’t carry significant structural weight from the construction above them. Instead, their main purpose is to create openings and divisions within a building for architectural, design, or practical purposes.

The advantages of non-load-bearing lintels are many. Given their primary function as design elements, these lintels allow architects and designers greater freedom to explore various aesthetics and styles. For instance, creating large open spaces or unique window shapes. Furthermore, since they don’t bear the heavy structural load, the material options are more varied, allowing for innovative and flexible design possibilities. The different types of lintels (non-load-bearing) are discussed below.

2.1 Plate Lintels

Plate lintels are often made of metal and used in non-load-bearing walls. These lintels can be made from various materials, but most commonly, they are fabricated from steel plates. They provide a flat, smooth finish that can easily be painted or decorated to match the surrounding wall. Their slim profile can be a great advantage when dealing with limited space or aiming for a minimalistic aesthetic.

2.2 Arch Lintels

Arch lintels are a classic choice, serving both functional and decorative purposes. They can be found in many historical buildings, displaying a range of architectural styles. They are formed in the shape of an arch, distributing the weight evenly to the side supports. Although they can serve as load-bearing lintels, in modern construction, they’re often used as non-load-bearing elements for their visual appeal.

2.3 Precast Concrete Lintels

Precast concrete lintels, even though primarily used as load-bearing lintels, can also be used in non-load-bearing situations. They are made in controlled factory environments, ensuring a high degree of consistency and quality. Their use in non-load-bearing applications often comes down to design preference, budget, or specific construction needs.

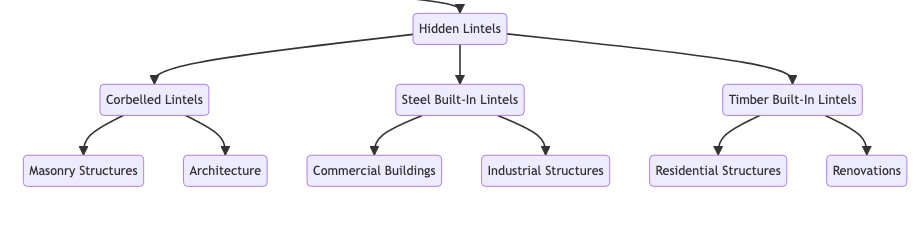

3. Hidden Lintels

Hidden lintels are just what their name suggests — they’re not immediately visible within the design of a structure. Often, they are built into the wall itself or masked with other construction materials.

Hidden lintels carry both aesthetic and structural benefits. From an aesthetic perspective, they provide a clean, unbroken visual line, ideal for modern minimalist architecture. From a structural perspective, they’re often used where it would be unfeasible or undesirable to disrupt the continuity of a wall with an overt lintel. The different types of lintels (hidden lintels) are discussed below.

3.1 Corbel Lintels

Corbel lintels are a type of hidden lintel that uses the technique of corbelling — a method of construction where each row of bricks or stones extends slightly beyond the one below. Over an opening, the two opposing corbel sections meet in the middle, forming a sort of arch. While often used in historical and traditional architecture, corbel lintels can also provide a unique visual touch to modern designs.

3.2 Steel Built-In Lintels

Steel built-in lintels are concealed within the wall structure, providing an unobtrusive and seamless appearance. Despite being hidden, they perform the necessary function of bearing and distributing loads. They are usually embedded into the wall during construction, hence providing strength without altering the visual continuity of the wall.

3.3 Timber Built-In Lintels

Just like their steel counterparts, timber built-in lintels are integrated into the wall structure, remaining unseen in the finished product. They are often used in timber frame construction and lend their strength to the structure without compromising on aesthetics. As a renewable resource, timber also adds a level of environmental sustainability to the construction.

4. Rolled Steel Joist Lintels

Rolled Steel Joist (RSJ) lintels, also known as I-beam lintels, are a type of structural steel shaped like an ‘I’. This construction element is commonly used in large-scale, heavy-duty building projects due to its impressive strength and load-bearing capacity.

The primary function of RSJ lintels is to provide support over openings, such as doors and windows, in construction. They have high load-bearing capabilities, making them an ideal choice for larger, more complex structures or buildings that require substantial support.

RSJ lintels come with numerous advantages. They are exceptionally strong and durable, making them resistant to warping, bending, and decay. Moreover, their shape provides superior load distribution capabilities. RSJ lintels are also resistant to fire and pests, adding an extra layer of protection to the structure. Furthermore, their production can be standardized, ensuring consistent quality.

There are several types of lintels (RSJ) used in construction, such as bent lintels, solid base plate lintels, and welded plate lintels.

4.1 Bent Lintels

Bent RSJ lintels are customized RSJ lintels bent into specific shapes to meet unique architectural needs. This flexibility allows them to support unusual or non-standard building features, making them a popular choice for bespoke building designs.

4.2 Solid Base Plate Lintels

Solid base plate RSJ lintels feature a base plate attached to the bottom flange of the RSJ. This base plate provides an extended bearing area, allowing for an improved load distribution and making them a preferred choice for heavy-duty load-bearing applications.

4.3 Welded Plate Lintels

Welded plate RSJ lintels are made by welding additional steel plates to the web of the RSJ. These additional plates increase the overall load-bearing capacity of the lintel. They’re typically used in construction projects requiring high strength and durability.

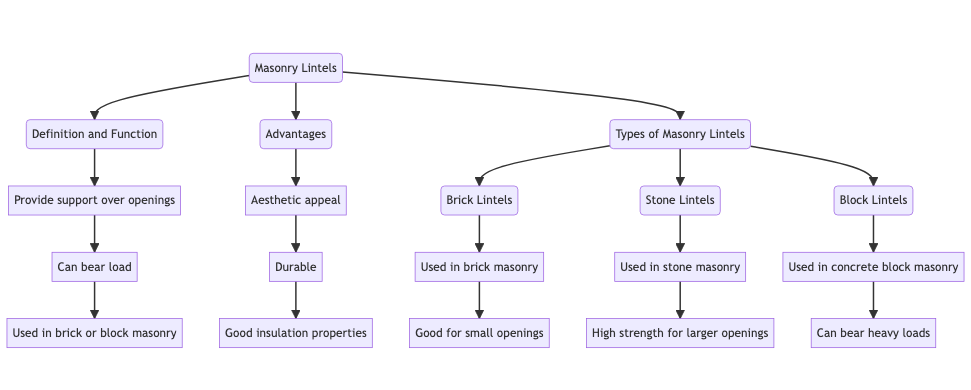

5. Masonry Lintels

Masonry lintels are a type of lintel made from masonry units such as bricks, stones, or concrete blocks. They serve the same primary function as other lintels, i.e., to support the load over an opening. Masonry lintels are often used because they can be made from the same material as the rest of the wall, providing a consistent and seamless aesthetic.

The main advantage of masonry lintels is their aesthetic appeal. As they can be constructed from the same material as the rest of the wall, they blend seamlessly into the structure, creating a unified look. They’re also highly durable and resistant to most forms of environmental damage. The different types of lintels (Masonry lintels) are discussed below.

5.1 Brick Lintels

Brick lintels are made from bricks and mortar and are often used when the rest of the construction is also brick. They’re appreciated for their visual consistency and the aesthetic appeal they bring to a structure. They’re strong and durable, capable of supporting considerable weight when constructed correctly.

5.2 Stone Lintels

Stone lintels are traditional lintels often seen in older buildings. They are strong and durable, and can support heavy loads. Stone lintels also add a significant aesthetic value to the structure and are often used in constructions aiming for a traditional or rustic look.

5.3 Block Lintels

Block lintels are constructed using concrete or cinder blocks. These lintels are typically used in constructions where the rest of the wall is also made of blocks. Block lintels are sturdy and reliable, providing excellent load-bearing capacity. They are also cost-effective and easy to install, making them a popular choice in construction.

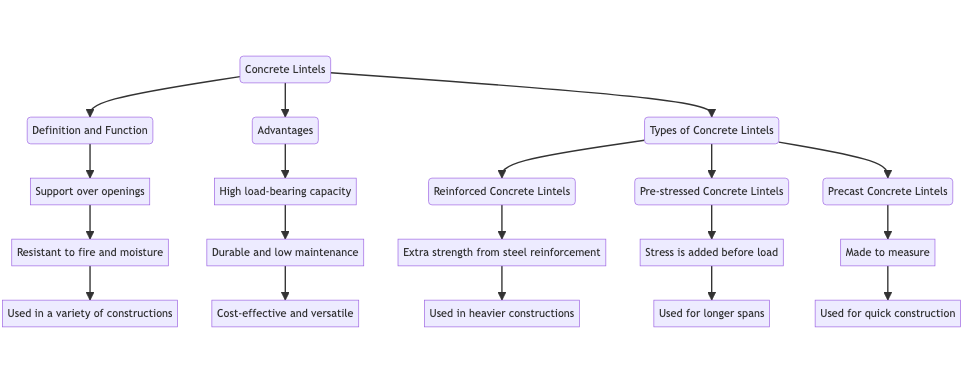

6. Concrete Lintels

Concrete lintels are a type of lintel made from concrete, a versatile and robust material used widely in construction. They play an integral role in building and construction, providing support over openings such as windows and doors. Concrete lintels are highly effective at bearing and distributing loads, ensuring the structural integrity of a building.

There are several advantages to using concrete lintels. One of the main benefits is their exceptional load-bearing capacity. They can support heavy loads, making them suitable for both residential and commercial construction. They also offer fire resistance, contributing to the overall safety of the structure. In addition, concrete lintels require little to no maintenance, further boosting their appeal. The different types of lintels (Concrete lintels) are discussed below.

6.1 Reinforced Concrete Lintels

Reinforced concrete lintels contain steel bars or mesh to enhance their tensile strength. This reinforcement allows the lintel to bear heavier loads and provides greater resistance to bending. These lintels are extremely strong and durable, making them a popular choice for large-scale construction projects.

6.2 Pre-stressed Concrete Lintels

Pre-stressed concrete lintels undergo a process during manufacturing that imparts internal stresses to counteract the tensile stresses that will be imposed during service. This pre-stressing results in lintels that are more resistant to cracking and have greater load-bearing capacity.

6.3 Precast Concrete Lintels

Precast concrete lintels are manufactured off-site and shipped to the construction site. They provide a high level of consistency and quality, as they are made in controlled factory environments. These lintels are highly durable, and their standardized sizes make them easy to work with.

7. Composite Lintels

Composite lintels are constructed using multiple materials to combine the strengths and advantages of each. They serve the same function as other types of lintels, i.e., providing support over openings in construction.

One of the primary advantages of composite lintels is their flexibility. As they can combine different materials, they offer a range of properties such as lightness, strength, and insulation. This can be customized to suit the specific needs of a construction project. Additionally, composite lintels can offer superior thermal performance, helping to improve the energy efficiency of a building. The different types of lintels (Composite lintels) are discussed below.

7.1 Polystyrene Lintels

Polystyrene lintels are lightweight, strong, and provide excellent thermal insulation. These lintels are typically used in conjunction with other materials to provide additional strength. Polystyrene lintels are ideal for energy-efficient construction projects, as they help to minimize thermal bridging.

7.2 Steel and Concrete Lintels

Steel and concrete composite lintels combine the tensile strength of steel with the compressive strength of concrete. These lintels provide high load-bearing capacity and durability, making them suitable for large, heavy-duty construction projects.

7.3 Glass Fibre Reinforced Lintels

Glass fibre reinforced lintels use a composite material made of a polymer matrix reinforced with glass fibres. These lintels are extremely strong yet lightweight, and resistant to corrosion. They offer superior thermal insulation and are suitable for environments where a metal lintel may corrode.

FAQ’s

What are the different types of lintels in construction?

There are several types of lintels used in construction, including load-bearing lintels, non-load-bearing lintels, hidden lintels, Rolled Steel Joist (RSJ) lintels, masonry lintels, concrete lintels, and composite lintels. Each type has its unique benefits and applications, varying in material and function.

What is the purpose of a lintel in building construction?

Lintels are crucial elements in building construction, providing support over openings like doors and windows. They help to bear and distribute the weight from the structure above, preventing structural failure and contributing to the overall stability of the building.

What are the advantages of using concrete lintels?

Concrete lintels have several advantages, including excellent load-bearing capacity, fire resistance, and low maintenance. They can support heavy loads, making them suitable for various construction projects. They are also available in reinforced, pre-stressed, and precast forms, each with their unique benefits.

How do composite lintels improve building efficiency?

Composite lintels can improve building efficiency in several ways. They are lightweight yet strong, capable of supporting substantial loads. They also offer superior thermal performance, reducing energy loss and contributing to the energy efficiency of a building.

What is the role of RSJ lintels in construction?

Rolled Steel Joist (RSJ) lintels or I-beam lintels are commonly used in large-scale, heavy-duty construction projects due to their impressive strength and load-bearing capacity. They provide strong support over openings, ensuring the structural integrity of a building.

How do masonry lintels contribute to the aesthetics of a building?

Masonry lintels, made from materials like brick, stone, or block, blend seamlessly into the structure, providing a consistent look. By using the same material as the rest of the wall, masonry lintels contribute to the aesthetic unity of the building.

What are the benefits of using pre-stressed concrete lintels?

Pre-stressed concrete lintels offer increased resistance to cracking and have a higher load-bearing capacity. The process of pre-stressing imparts internal stresses to counteract the tensile stresses that will be imposed during service, resulting in lintels with superior structural integrity.

What are hidden lintels and where are they used?

Hidden lintels are integrated into the wall structure, remaining unseen in the finished product. They are often used where it would be unfeasible or undesirable to disrupt the continuity of a wall with an overt lintel, providing an unobtrusive and seamless appearance.

What are the unique features of steel and concrete composite lintels?

Steel and concrete composite lintels combine the tensile strength of steel with the compressive strength of concrete. These lintels provide high load-bearing capacity and durability, making them suitable for large, heavy-duty construction projects.

Why are polystyrene lintels preferred in energy-efficient constructions?

Polystyrene lintels are lightweight, strong, and provide excellent thermal insulation. These properties make them ideal for energy-efficient construction projects as they help to minimize thermal bridging, thus contributing to energy conservation.

Read More

1 thought on “Top 20 Different Types of Lintels and their Uses”