Innovation is the pulse that keeps industries alive, thriving, and constantly evolving. The construction industry is no exception. Innovative materials are increasingly playing a pivotal role in shaping the future of this age-old industry, pushing boundaries, redefining standards, and reimagining what is possible.

In the realm of construction, innovative materials aren’t just a passing trend but they have become a necessity. As the world grapples with climatic challenges, population growth, urbanization, and a heightened focus on sustainability, there’s a mounting demand for building materials that are efficient, eco-friendly, and economical. Innovation, therefore, is no longer a luxury but an essential pathway to meeting these pressing global demands.

The benefits of using innovative materials in construction are multifold. Firstly, these advanced materials often come with improved properties such as higher durability, reduced weight, better insulation capabilities, or increased strength. This not only enhances the overall quality and longevity of the built structures but also opens up opportunities for novel architectural designs and applications.

Moreover, many innovative materials are geared towards sustainability, an aspect that is fast becoming a non-negotiable in the construction field. They help reduce the carbon footprint of buildings, minimize energy consumption, or even generate energy themselves. Utilizing such materials is a step towards green and sustainable construction, something that is not just beneficial for the environment, but is increasingly demanded by clients and legislation.

Efficiency is another critical advantage offered by innovative materials. In a world where time is money, materials that facilitate faster and easier construction without compromising on quality are a boon. For instance, certain advanced materials enable prefabrication, where parts of a building are manufactured in a factory and then assembled on site. This can significantly speed up construction time, reduce labor costs, and also minimize wastage.

Finally, innovative materials can also contribute to improved safety in buildings. From fire-resistant materials to those that can withstand natural calamities like earthquakes or hurricanes, advancements in material technology are continuously pushing the envelope in building safety standards.

In short, the role of innovative materials in the construction industry is not to be understated. These materials, aptly referred to as “smart materials,” are revolutionizing the way we build and live. They’re not just transforming our buildings, but also our lifestyles, economies, and ultimately, our planet. In the following sections, we are discussing the top 10 innovative materials that are leading this transformation in the construction industry.

1. Self-healing Concrete

As we dive into the world of innovative materials, the first one that warrants our attention is self-healing concrete. Yes, you read it right, ‘self-healing,’ much like a living organism. This remarkable material can repair its own cracks, a groundbreaking feat that holds immense potential for the construction industry.

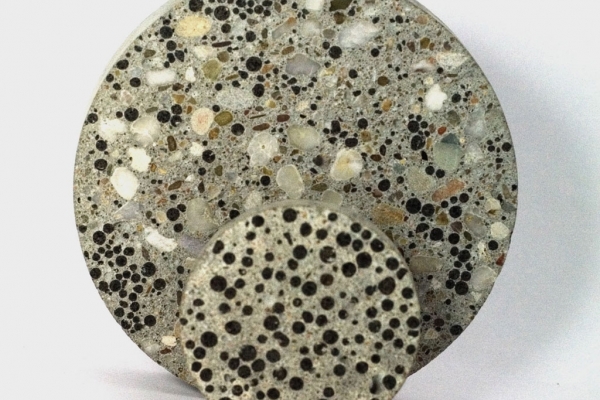

Concrete is one of the most widely used construction materials worldwide. Its strength, durability, and versatility have made it a go-to choice for everything from buildings and bridges to roads and dams. However, concrete is not without its weaknesses. One of the biggest issues is cracking, which can occur due to a variety of reasons such as shrinkage, thermal changes, stress, and environmental degradation. Cracks not only affect the structural integrity of the concrete, but they also provide an entryway for harmful substances like water, chemicals, and gases, which can lead to further deterioration. Traditionally, these cracks have to be manually repaired, a process that can be labor-intensive, costly, and disruptive.

Enter self-healing concrete – a smart material that promises to address this pervasive problem. The ‘healing’ ability of this innovative concrete comes from a type of bacteria, known as Bacillus bacteria, which are added to the concrete mix. These bacteria can survive in the harsh, alkaline environment of concrete for up to 200 years and are activated when water enters a crack. They produce limestone as a by-product of their metabolic process, which fills and seals the crack, thereby ‘healing’ the concrete.

The benefits of this fascinating technology are numerous. The most obvious one is that it significantly enhances the durability and lifespan of concrete structures. By healing cracks automatically, self-healing concrete can prevent the ingress of harmful substances and arrest the deterioration of the structure. This means that buildings made with self-healing concrete can remain safe and sound for much longer periods, reducing the need for frequent maintenance and repairs.

In the long run, this can translate into substantial cost savings. Consider the enormous amounts spent annually on the repair and maintenance of concrete structures worldwide. Self-healing concrete could potentially cut down these costs drastically. Plus, there are the indirect costs – like traffic disruption due to road repairs or loss of productivity due to building maintenance – which can also be minimized.

Moreover, self-healing concrete is a step towards sustainable construction. The production of cement, a key ingredient in concrete, is responsible for around 8% of global carbon dioxide emissions. By extending the life of concrete structures and reducing the need for new cement, self-healing concrete can help lower these emissions and contribute to a greener planet.

Looking at its future potential, it’s clear that self-healing concrete could be a game-changer. This technology is still in its early stages, and research is ongoing to improve the healing efficiency, reduce costs, and explore new types of bacteria for the process. In the coming years, we can expect to see wider applications of self-healing concrete, not just in buildings, but also in infrastructure like roads, bridges, tunnels, and more.

In summary, self-healing concrete is an epitome of how innovation can transform traditional materials and offer smart solutions to longstanding problems. With its impressive benefits and vast potential, this innovative material is undoubtedly set to revolutionize the construction industry, pushing it towards a future of greater durability, efficiency, and sustainability. This is just the beginning of our exploration into innovative materials. Stay tuned as we delve into more such exciting advancements in the following sections.

2. Aerogel Insulation

When it comes to innovation in the construction industry, the conversation can hardly proceed without mentioning aerogel insulation. This innovative material, which NASA has employed for space exploration, has a growing significance in the world of architecture and construction. The concept of aerogel insulation may sound futuristic, but its application is very real and very present.

Aerogels are among the lightest solid materials known to us, with a composition that is approximately 90-99% air. Despite this, they have remarkable insulation properties. The secret lies in the nanoscale structure of aerogels, which comprises a network of interconnected nanoparticles. This structure restricts the transfer of heat, making aerogels excellent insulators.

One of the most prominent types of aerogel used for insulation is silica aerogel. It is a porous, low-density material that, despite its ghostly, translucent appearance, has excellent thermal and acoustic insulation properties. It also exhibits superior fire resistance, making it an attractive option for a variety of construction applications.

The use of aerogel insulation in construction can bring a host of benefits. To begin with, aerogel’s superior insulation performance means that less material is required to achieve the desired thermal comfort levels in a building. This can not only save on material costs but also allow for more space-efficient designs. Imagine the possibilities in densely populated urban areas, where space is at a premium.

Another critical advantage of aerogel insulation is its contribution to energy efficiency. By effectively reducing heat loss or gain, aerogel can significantly lower the energy required for heating or cooling buildings. This can translate into considerable energy savings over the building’s lifespan, contributing to lower carbon emissions and promoting sustainable construction.

Aerogel insulation also boasts of excellent fire resistance. Its high melting point and low thermal conductivity make it a suitable material for fireproofing applications in buildings. Furthermore, aerogels are resistant to moisture and do not degrade over time, which can be a significant advantage in regions with high humidity or rainfall.

From a practical standpoint, aerogel insulation is easy to install. It usually comes in the form of blankets or panels that can be cut and shaped as per the requirements. This ease of installation, coupled with its long lifespan, makes aerogel a cost-effective insulation solution in the long run.

While the benefits of aerogel insulation are clear, the material does face some challenges, primarily related to its cost. Currently, aerogel insulation is relatively expensive compared to traditional insulation materials. However, as production processes improve and demand increases, we can expect the cost to come down in the future.

In terms of future potential, there’s a lot to look forward to with aerogel insulation. Researchers are exploring ways to produce aerogels from biodegradable and renewable sources, which could further boost their sustainability credentials. Moreover, advancements in nanotechnology are expected to lead to aerogels with even better properties and performance.

In conclusion, aerogel insulation stands as a prime example of how innovative materials can revolutionize traditional construction practices. With its superior insulation properties, contribution to energy efficiency, and vast potential, aerogel insulation is set to play an increasingly important role in the construction industry. As we strive towards a future of green and efficient buildings, aerogel insulation stands as a promising ally in that journey.

3. Transparent Aluminum

In the intriguing domain of innovative construction materials, let’s now turn our gaze towards a material that seems straight out of a science fiction novel – transparent aluminum. It’s a real-world material that possesses properties both of aluminum and of the more traditionally transparent material, glass. This incredible material has the potential to redefine the way we think about and use metals in construction.

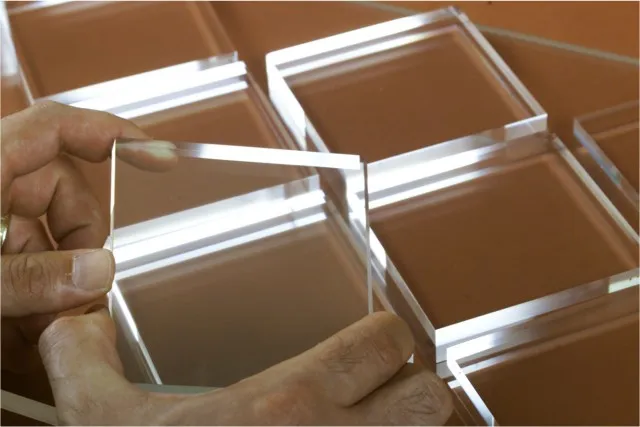

Transparent aluminum, technically referred to as Aluminum Oxynitride (ALON), is a ceramic compound with a unique combination of properties. It exhibits the strength and durability of aluminum, while also boasting of transparency comparable to glass. This allows for a sturdy, yet transparent material that can serve a multitude of purposes in construction.

Transparent aluminum is produced by a process involving high temperatures and pressures. This involves taking powdered aluminum and subjecting it to intense heat until it becomes a molten state. Nitrogen is then introduced to this heated mixture, eventually forming the transparent aluminum compound.

One of the main characteristics that makes transparent aluminum so attractive for construction and architectural applications is its high strength and durability. It’s said to be four times harder than fused silica glass and twice as hard as regular sapphire. This hardness translates into a high resistance to damage, be it from impact, abrasion, or weathering.

Transparent aluminum also has excellent optical properties. It allows a high amount of light to pass through, making it suitable for applications where visibility is required. However, unlike ordinary glass, transparent aluminum is also capable of blocking ultraviolet and infrared radiation, which can be advantageous in maintaining the thermal comfort of buildings and protecting occupants from harmful UV rays.

In terms of applications, transparent aluminum can be used anywhere conventional glass is used, but with the added benefits of higher strength and durability. This could include windows, skylights, and glazed partitions in buildings. Its high resistance to damage also makes it ideal for high-security applications such as bulletproof glass or blast-resistant structures.

Despite its impressive properties, the use of transparent aluminum is currently limited due to its high cost. The production process is complex and energy-intensive, which drives up the cost of the material. However, research is ongoing to develop more cost-effective production methods, and as the demand for this material grows, economies of scale could eventually bring the cost down.

Looking towards the future, the potential of transparent aluminum is vast. Imagine skyscrapers with transparent aluminum facades that not only offer stunning views but are also highly resistant to damage and weathering. Or consider the possibility of underwater structures with transparent walls that allow occupants to gaze into the depths of the ocean.

In conclusion, transparent aluminum is a prime example of how innovative materials are pushing the boundaries in construction. By combining the strength of metal with the transparency of glass, this material brings a whole new dimension to architectural design. While its use may currently be limited, there’s no denying that transparent aluminum has the potential to reshape the construction industry. As we continue to strive for stronger, safer, and more sustainable buildings, materials like transparent aluminum will undoubtedly play a crucial role.

4. 3D Printed Structures

As we traverse through the exciting terrain of innovative construction materials and methods, we can’t afford to overlook the advent of 3D printed structures. While 3D printing, or additive manufacturing, has been around for some time in various industries, its application in construction is relatively recent. This cutting-edge technology opens up an entirely new frontier for the building sector, offering faster, cheaper, and more sustainable construction possibilities.

To understand how 3D printing works in the construction industry, imagine a giant 3D printer. Instead of ink or plastic, this printer uses a special type of concrete or other building materials. It operates on a set of digital instructions, or a blueprint, and layers the material accordingly, creating a three-dimensional structure piece by piece. This can be done in two ways: either components of the structure are printed separately and then assembled on site, or the entire structure is printed on site, all at once.

3D printed structures hold immense promise for the future of construction, the most significant of which is the potential for automation. The construction process can be largely automated using 3D printers, reducing the need for manual labor. This could result in faster and more efficient construction, not to mention safer worksites by reducing the risk of accidents.

Additionally, 3D printing can lead to significant cost savings. By automating the construction process, it can reduce labor costs. Plus, 3D printers are precise, which means they can minimize waste by using just the right amount of material needed for the structure. This precision also means that 3D printed structures can be built with intricate designs and complex geometries that would be challenging or even impossible with traditional construction methods.

Sustainability is another key advantage of 3D printed structures. By minimizing waste, 3D printing can help conserve resources and reduce the environmental impact of construction. Some 3D printers are even capable of using recycled materials, further contributing to sustainable construction. Moreover, the possibility of on-site printing can reduce the need for transportation of materials, which can significantly lower carbon emissions.

Despite these benefits, it’s important to note that 3D printing in construction is still in its early stages. While there have been successful demonstrations of 3D printed houses and bridges, the technology is yet to be adopted widely. There are challenges to overcome, including developing suitable materials for 3D printing, ensuring the durability and safety of 3D printed structures, and navigating regulatory hurdles.

Nevertheless, the future potential of 3D printed structures is undeniable. With continued advancements in technology and materials, we can expect to see more and more 3D printed buildings in the future. Imagine neighborhoods with custom-designed 3D printed homes, built quickly and affordably. Or consider disaster-prone areas where emergency shelters could be printed on-demand in a matter of hours. The possibilities are as boundless as our imagination.

In conclusion, 3D printed structures represent a radical shift in the way we think about construction. By harnessing the power of digital technology and automation, 3D printing offers a future where buildings are constructed faster, cheaper, and more sustainably. As we continue to explore innovative materials and methods in construction, 3D printing stands out as a game-changing technology that is set to redefine the industry.

5. Graphene

A discussion about innovative materials would be incomplete without mention of graphene, a material that’s been stirring excitement across multiple industries. Graphene’s unique properties and vast potential make it a material to watch in the construction industry, where it could herald a new era of stronger, lighter, and more efficient structures.

Graphene is a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice. It was first isolated in 2004, and its discovery has sparked an explosion of research due to its exceptional properties. It is, for instance, approximately 200 times stronger than steel by weight, making it the strongest material ever tested. It is also incredibly thin, flexible, and lightweight, while also being an excellent conductor of heat and electricity.

What does all this mean for the construction industry? To start, graphene’s superior strength and lightness could revolutionize the way we build. Imagine a skyscraper made with graphene-reinforced materials, standing taller and stronger than ever before, yet requiring far less material to construct. This could lead to massive savings in material costs and a significant reduction in the environmental footprint of buildings.

Graphene also has the potential to enhance the performance of existing construction materials. For example, when mixed with concrete, graphene can significantly increase its tensile strength and reduce water permeability, making the concrete more durable and resistant to corrosion. This could extend the lifespan of structures and reduce maintenance costs. Similarly, incorporating graphene into metals, plastics, or other materials can improve their properties and performance.

The thermal and electrical conductivity of graphene can also be harnessed in the built environment. For instance, graphene-infused paints or coatings could regulate the temperature of buildings by efficiently dissipating or conserving heat, reducing the need for energy-intensive heating and cooling systems. Graphene-based sensors could also be embedded into buildings to monitor structural integrity, temperature, humidity, and more, leading to smarter and safer structures.

Despite its vast potential, the use of graphene in construction is still in its nascent stages. Challenges exist, not least of which is the high cost of graphene production. While techniques for producing graphene have improved since its discovery, producing it at a scale and cost that would make it viable for widespread construction use is still a challenge. However, ongoing research and technological advancements are expected to bring down these costs in the future.

The potential health and environmental impacts of graphene are also being carefully studied. As a nanomaterial, graphene’s tiny size means it can behave in ways that larger materials do not, which can have implications for human health and the environment. Ensuring the safe and responsible use of graphene will be crucial as we explore its potential applications in construction.

Looking towards the future, the possibilities for graphene in construction are immense. As production techniques improve and we learn more about how to work with this material, graphene could redefine what’s possible in construction. We can look forward to a future where our buildings are stronger, lighter, more efficient, and smarter, thanks to the incorporation of innovative materials like graphene.

In conclusion, graphene stands out as one of the most promising materials in the innovation-driven landscape of construction. Its unique properties offer solutions to some of the key challenges the industry faces, such as improving structural performance, enhancing sustainability, and creating smarter buildings. As we continue to push the boundaries of innovation in construction, materials like graphene will undoubtedly play a pivotal role.

6. Phase Changing Materials (PCMs)

As we delve deeper into the world of innovative materials in construction, we encounter an exciting development that’s set to transform how we manage temperature within our built environment – Phase Changing Materials, or PCMs. As a key player in the realm of green building materials, PCMs offer promising solutions to enhance energy efficiency and comfort in buildings.

Phase Changing Materials are substances that absorb or release thermal energy when they change their state – for instance, from solid to liquid or vice versa. When a PCM absorbs heat, it melts and changes from a solid state to a liquid state, storing the heat in the process. Conversely, when it cools down, it solidifies and releases the stored heat. This unique property allows PCMs to act as thermal batteries, storing excess heat and releasing it when needed.

In the context of construction, PCMs can be incorporated into a building’s structure or materials to help regulate the indoor temperature. They can be embedded in walls, floors, ceilings, or even within the material of bricks or panels. As the building heats up during the day, the PCM absorbs and stores the excess heat, preventing the indoor temperature from rising too high. Then, as the building cools down at night, the PCM solidifies and releases the stored heat, helping to maintain a comfortable indoor temperature.

The benefits of using PCMs in construction are manifold. First and foremost, they can significantly enhance energy efficiency. By smoothing out temperature fluctuations within the building, PCMs can reduce the need for energy-intensive heating and cooling systems, leading to substantial energy savings. In turn, this can lead to lower utility bills and a smaller carbon footprint for the building.

PCMs also contribute to improved comfort within the building. By maintaining a more stable indoor temperature, they can create a more comfortable environment for the building’s occupants. Plus, unlike traditional heating or cooling systems, PCMs operate silently and without any moving parts, further enhancing comfort.

Moreover, PCMs offer a passive solution to temperature regulation. Unlike active systems such as air conditioning or heating, which require constant energy input to function, PCMs work passively, absorbing and releasing heat as the ambient temperature changes. This not only makes them more energy-efficient but also more reliable and low-maintenance.

Despite their potential, the use of PCMs in construction is still relatively new, and challenges remain. For instance, selecting the right PCM for a specific application is crucial, as different PCMs have different melting points and heat storage capacities. Furthermore, the integration of PCMs into construction materials needs to be done carefully to ensure durability and safety.

Looking to the future, it’s clear that PCMs have a crucial role to play in creating more sustainable, energy-efficient buildings. As we continue to search for ways to reduce the environmental impact of our built environment, technologies like PCMs offer promising solutions.

In conclusion, Phase Changing Materials represent an exciting development in the field of innovative construction materials. Their unique properties and potential to enhance energy efficiency make them a powerful tool in the pursuit of greener, more sustainable buildings. As we continue to innovate and push the boundaries of what’s possible in construction, materials like PCMs are set to play a starring role.

7. Biomimetic Materials

Nature, in its profound wisdom, has perfected the art of creating efficient, resilient, and sustainable systems over billions of years of evolution. Biomimetic materials, as the name suggests, draw inspiration from nature’s ingenuity to develop new and innovative solutions. These materials imitate the structures, properties, and functions of biological systems, offering exciting possibilities for sustainable construction and innovation in the building sector.

Biomimetics – the practice of learning from and mimicking nature – is not a new concept, but its application in construction materials is gaining momentum as we strive to create more sustainable and resilient built environments. By looking closely at the natural world, researchers and scientists have been able to create materials that mimic some of the most amazing traits found in biology, from the self-healing abilities of trees to the structural efficiency of honeycombs.

Let’s take a closer look at how biomimetic materials are poised to transform the construction industry.

One promising area of biomimetic materials is the development of self-healing concrete. Much like a tree that can seal its own wounds, self-healing concrete contains bacteria that produce limestone when exposed to water, effectively sealing any cracks that form. This can greatly extend the life of the concrete, reducing maintenance costs and improving sustainability.

Another fascinating example is the development of materials inspired by the structure of bird bones. Bird bones are incredibly strong for their weight, thanks to their hollow, honeycomb-like structure. By mimicking this structure, we can create materials that are both lightweight and strong – a valuable trait for reducing the material usage in buildings without compromising structural integrity.

Biomimetic materials can also help improve energy efficiency in buildings. For instance, certain types of beetles in the Namib desert can harvest water from fog, thanks to the unique structure of their shells. By mimicking this structure, we can create surfaces that condense water vapor from the air, potentially providing a passive cooling effect and reducing the need for air conditioning.

The benefits of biomimetic materials in construction are compelling. These materials can help us build more sustainably, efficiently, and resiliently, reducing our impact on the environment and creating healthier, more comfortable living spaces. They also offer solutions to some of the key challenges we face in construction, such as reducing energy consumption, minimizing material usage, and extending the lifespan of structures.

However, the development and adoption of biomimetic materials in construction is still in its early stages. Challenges remain, including the need for more research to understand and replicate complex biological systems, and the need to scale up production processes to make these materials economically viable for widespread use.

Despite these challenges, the potential of biomimetic materials in construction is immense. As we continue to explore and innovate, we can expect to see more and more nature-inspired solutions coming to the forefront of the construction industry.

In conclusion, biomimetic materials represent a fascinating and promising direction in the field of innovative construction materials. By looking to nature for inspiration, we can find solutions to some of our most pressing challenges, paving the way for a more sustainable and resilient future for the construction industry. As we continue to push the boundaries of what’s possible, biomimetic materials will undoubtedly play an increasingly important role.

8. Nanomaterials

Nanotechnology, the science of manipulating matter on an atomic and molecular scale, has evolved into a frontier of research and development in many sectors, including construction. Nanomaterials – materials that have at least one dimension measuring less than 100 nanometers – are central to this advancement. They possess unique properties that can enhance the characteristics of traditional construction materials, opening new avenues for the construction industry to explore.

Nanomaterials come in a variety of forms, such as nanoparticles, nanocomposites, and nanocoatings. By manipulating the structure of matter at the nanoscale, scientists can enhance or introduce new properties to the materials, such as increased strength, durability, or energy efficiency.

One of the key areas where nanomaterials are making a significant impact is in the improvement of concrete. Nanosilica, for instance, can be added to the concrete mixture to enhance its strength and durability. It works by filling the microscopic voids in the concrete, resulting in a denser, stronger material. Furthermore, the addition of nanosilica improves the hydration process of the cement paste, reducing the curing time and increasing the longevity of the structure.

Nanotechnology can also lead to smarter materials with new functionalities. For instance, Titanium Dioxide (TiO2) nanoparticles can be used in coatings to provide self-cleaning properties to surfaces. When exposed to sunlight, the nanoparticles catalyze a reaction that breaks down organic pollutants, effectively cleaning the surface. This has significant implications for maintaining the aesthetic and functional aspects of buildings, especially in urban environments.

Nanomaterials also have the potential to enhance insulation materials, thus improving energy efficiency in buildings. Aerogels, for example, are highly porous materials composed of a network of nanosized particles. They offer exceptional thermal insulation properties, thereby reducing the energy required for heating and cooling buildings.

The advantages of nanomaterials extend beyond enhanced physical properties and performance. These innovative materials also contribute to the sustainable development of the construction sector. Enhanced durability means structures that last longer, reducing the need for replacement and, therefore, resource consumption. Moreover, energy-efficient buildings lower the demand for energy, reducing CO2 emissions and contributing to the fight against climate change.

Despite the promising potential of nanomaterials, their application in the construction industry is not without challenges. One of the key hurdles is the cost associated with their production and use. Many nanomaterials are expensive to produce at scale, making their widespread use in construction currently limited. Additionally, there are ongoing debates about the health and environmental impacts of nanomaterials, and further research is needed to fully understand and mitigate these concerns.

However, as research progresses and manufacturing technologies evolve, the cost-effectiveness of nanomaterials is expected to improve, leading to their increased adoption in the construction industry. Furthermore, ongoing research and regulation will help to address the potential environmental and health risks associated with these materials.

In conclusion, nanomaterials are poised to revolutionize the construction industry by enhancing the properties of traditional construction materials. They provide innovative solutions to the sector’s challenges, including durability, energy efficiency, and sustainability. As we continue to innovate and embrace advanced construction technology, nanomaterials will undoubtedly play a key role in the future of construction.

9. Smart Glass

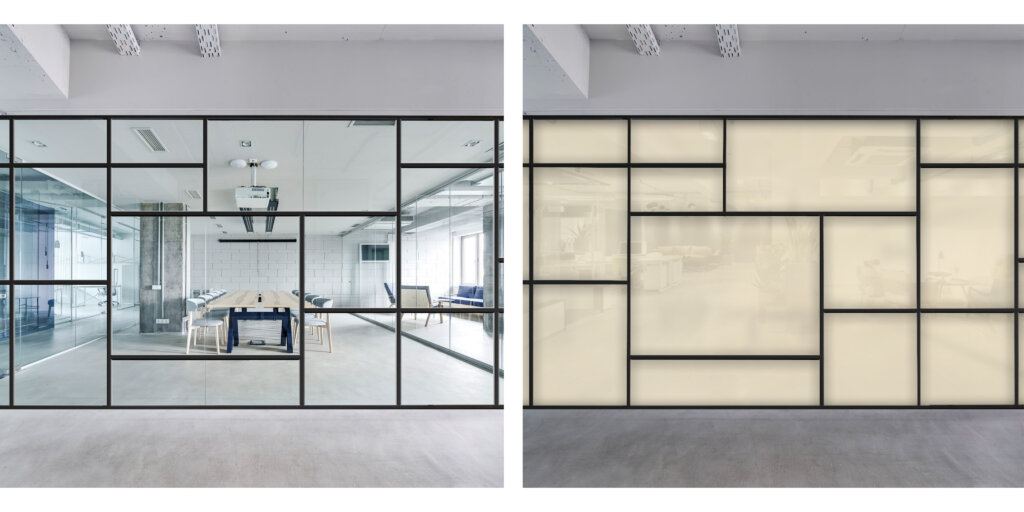

In the ever-evolving world of construction, smart glass stands out as a pioneering innovation that combines technology and building materials to create a more comfortable and energy-efficient living and working environment. It represents a transformative solution that not only caters to aesthetic appeal but also contributes significantly to green building practices.

Smart glass, also known as switchable glass or dynamic glass, adjusts its properties based on specific environmental or electrical stimuli. For instance, it can change its light transmission properties when influenced by light, temperature, or electricity, enabling it to switch from transparent to translucent and vice versa.

One of the most popular types of smart glass is electrochromic glass. It uses a small burst of electricity to trigger a chemical reaction that changes the glass’s opacity. The electricity charges the ions on the window surface, causing them to absorb light and darken. When the electrical charge is removed, the ions return to their previous state, causing the glass to lighten. This technology allows occupants to control the amount of light and heat entering a building, enhancing comfort and reducing reliance on artificial lighting and air conditioning.

Another type is thermochromic glass, which responds to heat. When the temperature rises, the glass darkens to block heat, and when the temperature falls, the glass lightens to let in more heat. This automatic response to the environment helps to regulate the interior temperature of a building, contributing to energy efficiency.

The benefits of smart glass are multifaceted. It offers enhanced control over light and privacy, allowing occupants to easily adjust the glass’s transparency as per their needs. This can be especially beneficial in spaces where maintaining privacy without blocking out natural light is a priority, such as offices or healthcare facilities.

Moreover, smart glass significantly contributes to energy efficiency. By controlling the amount of sunlight entering a building, it reduces the need for air conditioning in the summer and heating in the winter, thereby reducing energy consumption and CO2 emissions. According to the U.S. Department of Energy, smart windows could reduce energy costs by up to 20%.

Smart glass also contributes to the health and wellbeing of building occupants. By allowing for optimal natural light, it can enhance productivity and mood, as numerous studies have linked exposure to natural light to increased wellbeing and productivity.

However, like any technology, smart glass comes with challenges. The upfront costs are higher than traditional glass, making it a significant investment. But these costs can be offset over time through energy savings. Moreover, while the technology has come a long way, there are still opportunities for improvement in terms of the speed of switching between states and the range of tints available.

In conclusion, smart glass represents a powerful innovation in the construction industry. It offers a unique combination of aesthetic appeal, energy efficiency, and occupant comfort, aligning with the growing emphasis on sustainable and human-centered design in architecture. As we continue to strive for green building practices, smart glass and its future iterations will undoubtedly play a critical role in shaping our built environment.

10. Carbon Fiber

The quest for materials that offer superior strength, durability, and flexibility has led to significant advancements in the construction industry. One such advancement is the development and use of carbon fiber, a strong, lightweight material that holds great promise for revolutionizing the industry.

Carbon fiber, also known as graphite fiber, is a material consisting of thin strands of carbon atoms bonded linearly. These fibers are then twisted together to form a yarn, which can be used as is or woven into a fabric. The resulting material is incredibly strong, lightweight, and resistant to many types of damage.

In terms of strength, carbon fiber outperforms many traditional construction materials. It’s approximately five times stronger than steel and twice as stiff, yet it’s considerably lighter. This strength-to-weight ratio makes carbon fiber an appealing alternative to traditional steel reinforcements in concrete structures, allowing for more flexible and creative designs without sacrificing structural integrity.

The use of carbon fiber can be particularly beneficial in retrofitting and repairing aging structures. Carbon fiber reinforced polymers (CFRP) can be used to strengthen concrete, wood, or steel structures, adding to their load-bearing capacity and extending their lifespan. The lightweight nature of CFRP also means less additional weight is added to the existing structure, reducing the risk of overloading.

Carbon fiber’s high corrosion resistance is another of its significant benefits. Unlike steel, carbon fiber doesn’t rust, making it an ideal choice for structures exposed to corrosive elements, such as bridges, piers, or any construction near water bodies.

Beyond these strengths, carbon fiber also offers high temperature tolerance and excellent fatigue properties. It can withstand a wide range of temperatures and is resistant to many chemicals, extending its durability and reducing maintenance requirements.

Despite these impressive attributes, the use of carbon fiber in the construction industry is currently limited by a few factors. The primary barrier is cost. While prices have been declining as production methods improve and demand increases, carbon fiber still costs significantly more than traditional construction materials like steel.

Another challenge is that while carbon fiber is incredibly strong when subjected to tension, it’s not as strong when compressed. This characteristic can limit its use in certain applications unless it’s combined with other materials to create a composite that can withstand compressive forces.

As research continues and technology advances, we can expect to see these challenges gradually being overcome, leading to wider adoption of carbon fiber in the construction industry. The future of carbon fiber in construction looks promising, with potential applications in high-rise buildings, bridges, tunnels, and even space structures.

In conclusion, carbon fiber stands out as a game-changing material in the construction industry. With its superior strength, lightweight nature, corrosion resistance, and flexibility, it embodies the innovation that’s driving the future of construction. As the industry continues to evolve, the utilization of materials like carbon fiber will likely become more prevalent, leading to safer, more efficient, and more innovative building practices.

FAQ’s

What is self-healing concrete and how does it work?

Self-healing concrete is a type of innovative concrete that has the ability to heal its own cracks. It is embedded with bacteria that, when exposed to water, produce limestone, effectively filling in the cracks and prolonging the structure’s lifespan. This technology has the potential to significantly reduce maintenance costs and enhance the durability of construction projects.

How does aerogel insulation improve energy efficiency in buildings?

Aerogel insulation, one of the lightest solid materials in existence, offers exceptional thermal insulation properties. It effectively minimizes heat transfer, helping maintain a consistent indoor temperature regardless of outdoor conditions. This ability reduces the need for artificial heating or cooling, leading to substantial energy savings and promoting a more sustainable built environment.

What are the potential applications of transparent aluminum in construction?

Transparent aluminum, also known as aluminum oxynitride, is a strong and lightweight material with a high resistance to damage and a transparency similar to glass. Potential applications in construction include high-security windows, skylights, or any scenario where a combination of transparency, light weight, and high strength are desirable.

How do 3D printed structures transform the construction industry?

3D printed structures enable quicker, more efficient construction with reduced waste. By printing building components layer by layer, complex designs can be realized with less manual labor and material waste, potentially saving time and costs. They also allow for greater design flexibility, unlocking new possibilities in architectural design.

What role does graphene play in building materials innovation?

Graphene is a thin layer of pure carbon that is exceptionally strong, lightweight, and conductive. Its properties can significantly enhance traditional building materials. For example, adding graphene to concrete can increase its compressive and tensile strength, making structures more resilient. Moreover, its conductive properties open up possibilities for smart, energy-efficient buildings.

How do phase changing materials (PCMs) contribute to temperature control in buildings?

PCMs absorb or release thermal energy during phase transitions, such as solidifying or melting, thus regulating a building’s interior temperature. By integrating PCMs into building materials, buildings can naturally respond to temperature fluctuations, reducing the need for mechanical heating and cooling and enhancing energy efficiency.

What are biomimetic materials in construction?

Biomimetic materials are designed to mimic the structures, systems, and processes found in nature. They can contribute to sustainable construction by providing efficient, low-impact solutions. Examples include materials that mimic the cooling properties of termite mounds or the self-cleaning abilities of lotus leaves.

What are the benefits of using Nanomaterials in construction?

Nanomaterials, which have dimensions at the nanometer scale, can enhance the properties of traditional construction materials. For example, nano silica in concrete can improve its strength and durability, while nano-titanium dioxide can provide self-cleaning properties.

How does smart glass contribute to green building practices?

Smart glass, or switchable glass, can change its light transmission properties based on light, heat, or electrical stimuli. This allows for control over light and heat entering a building, reducing the need for artificial lighting and air conditioning and contributing to energy efficiency and comfort.

What are the advantages of carbon fiber in construction?

Carbon fiber is a strong, lightweight, and corrosion-resistant material. It can outperform steel in terms of strength-to-weight ratio, allowing for more flexible and innovative designs. Its corrosion resistance makes it ideal for structures exposed to corrosive elements, and its lightweight nature makes it suitable for retrofitting existing structures.

Read More

2 thoughts on “Top 10 Innovative Materials Transforming the Construction Industry”