When it comes to laying concrete, few tools are as indispensable as the humble concrete rake. While it might appear simple in design, the concrete rake serves as a fundamental tool in the construction industry. It’s an essential item in the toolkit of every concrete contractor, helping in the spreading and placement of concrete effectively.

Concrete rakes are built to serve a specific purpose. This particular tool is robust, designed to endure the rough-and-tough nature of construction sites. But, what is a concrete rake? And what are the different types of concrete rakes available? Furthermore, how do you achieve a concrete rake finish? These are questions we aim to answer in this comprehensive guide.

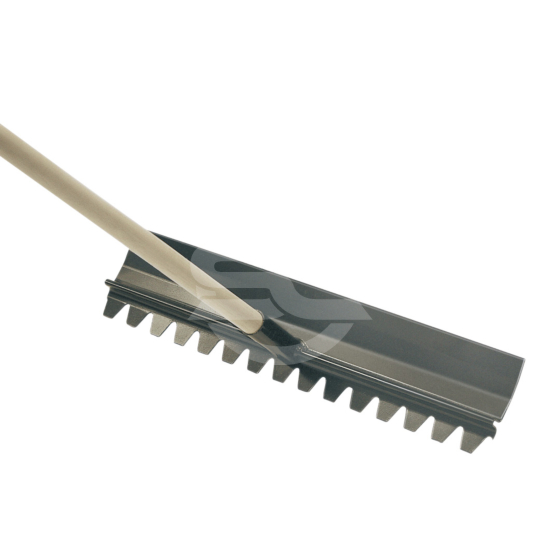

What comes to mind when you hear “concrete rake”? It may conjure images of a regular garden rake, but with a broader and tougher structure. And you wouldn’t be far off! A concrete rake, also referred to by some as a come-along, is a tool designed specifically for moving, spreading, and leveling freshly poured concrete. The head of the rake has a scoop design, enabling it to pull the concrete into place, while the long handle allows the user to do the job standing up, keeping them clear of the fresh concrete.

Concrete rakes serve multiple purposes, but their most essential role is in spreading concrete. If you’ve ever watched a road or a house slab being laid, chances are, you’ve seen a concrete rake in action. Contractors drag these rakes through wet concrete, distributing it evenly across a given area, ensuring that the concrete is spread out smoothly, and then allowing for additional tools to level it off to precision.

One of the most popular types of concrete rakes available in the market today is the aluminum concrete rake. This rake type is lightweight and resistant to rust, making it an excellent choice for many contractors. Moreover, with reinforced handles, these rakes can withstand the heavy load of concrete without bending or breaking.

While aluminum concrete rakes are commonly used, another popular variant that deserves mention is the concrete rake from Lowe’s, a well-known home improvement company. The concrete rake Lowes provides is robust, durable, and designed to handle the wear and tear of construction work. They come in different designs to cater to specific needs of the task at hand, providing the essential tool that many contractors need to distribute, grade, and shape concrete effectively.

Therefore, concrete rakes play an essential role in any construction project. Regardless of whether you’re using an aluminum concrete rake or a concrete rake from Lowes, the importance of this tool cannot be understated. As we continue, we’ll dive deeper into the different types of concrete rakes available, how to use them effectively, and best practices for maintenance to ensure your tool lasts as long as your structures do.

1. What is a Concrete Rake?

The world of construction, particularly concrete construction, is filled with specialized tools that are uniquely designed to carry out specific tasks. A prime example of this is the concrete rake. Not to be confused with the garden rake you might use to gather leaves in your backyard, a concrete rake is a much sturdier tool, designed for the specific task of manipulating, spreading, and leveling concrete.

At first glance, a concrete rake might look quite similar to the regular garden rake. However, when you delve into its structure and purpose, it’s clear that this robust tool has a significant role to play in the construction industry. The concrete rake’s primary function is to move, spread, and level freshly poured concrete. It’s an essential tool in creating a professional and even concrete finish, hence its importance on any construction site.

A typical concrete rake consists of three primary components: the handle, the head, and the tines.

The Handle: This part of the concrete rake is longer than what you’d find on a garden rake. The extended length of the handle allows workers to reach across the expanse of wet concrete without having to step into it. Handles can be made from different materials, but the most common are wooden and aluminum handles. Aluminum handles are particularly popular in models like the aluminum concrete rake because they offer a lightweight yet sturdy control for the operator.

The Head: The head of a concrete rake is considerably broader and more substantial than a regular rake. It’s designed to withstand the weight of wet concrete and be dragged through it without breaking. The head’s design can vary depending on the type of concrete rake. For instance, a concrete rake from Lowes might have a head with a slightly different shape compared to other brands.

The Tines: Unlike a garden rake that has many tines, a concrete rake typically has fewer tines, and they are more substantial, ensuring they can pull through heavy, wet concrete. In some types of concrete rakes, the tines are replaced by a single lip or blade to give a smoother finish.

The concrete rake finish achieved is directly dependent on how well this tool is used. A worker skilled in handling a concrete rake can use it to evenly distribute concrete over a large area, break up clumps, and push excess concrete away from certain areas. The result is a level, evenly distributed layer of concrete, ready for further finishing processes.

2. Why Do You Need a Concrete Rake?

Concrete rakes play a critical role in construction work. They may not carry the flashy appeal of a power tool, but they’re just as essential. If you’ve ever marveled at the smooth finish of a concrete floor or the even surface of a newly-paved sidewalk, you’ve seen the results of a well-used concrete rake. This section explores the role of concrete rakes in concrete laying and leveling and the benefits they bring to the construction industry.

The first and foremost role of a concrete rake is in the distribution of freshly poured concrete. When concrete is poured onto a surface, it doesn’t spread evenly by itself. It requires the help of a tool to distribute it across the area. This is where the concrete rake comes in. With its wide head and robust tines or lip, a concrete rake is used to pull and push the concrete around, spreading it evenly across the required area. This ensures that the concrete is evenly distributed before it begins to set.

Once the concrete is spread across the area, a concrete rake is again employed for leveling. This involves pulling the rake across the surface of the concrete to create a level finish. This might seem like a straightforward task, but it requires a certain degree of skill and precision. Achieving a smooth, level finish is critical as it affects the concrete’s final appearance and performance.

An aluminum concrete rake is particularly suitable for this job due to its lightweight yet sturdy construction. Its lightness makes it easy to maneuver, enabling the user to create an even and level finish with minimal effort. On the other hand, a concrete rake Lowes provides ensures high performance and durability, making it a preferred choice for many professionals.

In addition to concrete distribution and leveling, concrete rakes can also be used for breaking up lumps in the concrete mix, pushing excess concrete away from certain areas, and scraping the sides of the formwork to remove excess concrete.

The benefits of using a concrete rake in construction work are as follows:

- Efficiency: Concrete rakes increase work efficiency by enabling workers to spread and level concrete more quickly and easily. The time saved here can be used for other critical tasks on the construction site.

- Versatility: From spreading and leveling to breaking and scraping, concrete rakes can handle a variety of tasks, making them a versatile tool in the construction industry.

- Durability: Concrete rakes are designed to be robust and durable. Whether you choose an aluminum concrete rake or a concrete rake from Lowes, you can be sure of a tool that can withstand the demanding nature of construction work.

- Ease of Use: Despite their ruggedness, concrete rakes are fairly easy to use. They require minimal technical know-how, making them accessible to everyone from experienced contractors to DIY enthusiasts.

To sum it up, the concrete rake plays a pivotal role in the concrete laying and leveling process, making it an invaluable tool in the construction industry. The benefits it brings to the table in terms of efficiency, versatility, durability, and ease of use, only add to its appeal, making it a must-have tool for anyone involved in concrete work.

3. Different Types of Concrete Rakes

In the construction industry, concrete rakes are indispensable tools designed for moving, spreading, and leveling freshly poured concrete. A well-utilized concrete rake can make all the difference in achieving a professional concrete finish. But, not all concrete rakes are created equal. Depending on the specific needs of a project, different types of concrete rakes can be employed. In this section, we will delve into 10 different types of concrete rakes, their uses, as well as the pros and cons of each.

3.1 Standard Concrete Rake

The standard concrete rake, sometimes referred to as a come-along, is the most common type. It features a deep bit, allowing it to gather a large amount of material, and a long handle for extended reach. Standard concrete rakes are ideal for general concrete spreading tasks on large, flat areas.

Pros: Easy to use, versatile, and suitable for most concrete jobs.

Cons: Might be too large for detail work or confined spaces.

3.2 Aluminum Concrete Rake

Aluminum concrete rakes are lightweight, making them easier to use over extended periods. They are durable and rust-resistant, making them a good choice for jobs in wet environments.

Pros: Lightweight, durable, rust-resistant.

Cons: Could bend under heavy loads due to the lighter material.

3.3 Magnesium Concrete Rake

Magnesium concrete rakes are another lightweight option that is more durable and resistant to bending than aluminum. They are also corrosion-resistant, making them suitable for use in all weather conditions.

Pros: Lightweight, highly durable, corrosion-resistant.

Cons: More expensive than other types of concrete rakes.

3.4 Steel Concrete Rake

Steel concrete rakes are more robust and can handle heavier loads than their aluminum and magnesium counterparts. These rakes are great for heavy-duty work but may be too heavy for some users to handle comfortably for extended periods.

Pros: Strong, durable, able to handle heavy loads.

Cons: Heavy, can rust if not properly maintained.

3.5 Concrete Landscape Rake

Landscape concrete rakes have a wide head, making them perfect for spreading concrete over large areas. They also feature rounded teeth, allowing them to create a textured finish in the concrete.

Pros: Great for spreading concrete, can create texture.

Cons: Not suitable for detail work.

3.6 Concrete Placer Rake

Concrete placer rakes, also known as lute rakes, have a specific design with a long, straight edge on one side and a row of sharp, pointed teeth on the other. This design allows the rake to both spread and comb through the concrete, making it an extremely versatile tool.

Pros: Versatile, great for both spreading and combing through concrete.

Cons: The design may not be as efficient for larger scale jobs.

3.7 Concrete Rake with Hook

This type of rake features a hooked edge opposite the tines. The hook can be used to pull rebar or mesh into position while the concrete is still wet, making this rake an excellent choice for projects that incorporate these materials.

Pros: Dual-purpose, perfect for jobs involving rebar or mesh.

Cons: Might not be necessary for projects that don’t involve rebar or mesh.

3.8 Adjustable Concrete Rake

Adjustable concrete rakes come with telescoping handles that allow you to adjust the length of the handle according to your needs. This feature makes it easier to reach across larger areas or work in tight spaces.

Pros: Versatile, good for working in variable spaces.

Cons: The adjustable mechanism may wear out over time.

3.9 Roller Concrete Rake

Roller concrete rakes feature a large roller instead of a traditional head. The roller aids in pushing and pulling concrete while creating a smooth surface, making it ideal for decorative or finish work.

Pros: Creates a smooth finish, great for decorative concrete work.

Cons: Not ideal for general concrete spreading.

3.10 Asphalt/Concrete Rake

These are dual-purpose rakes designed to work with both asphalt and concrete. They usually have a wider head and shorter teeth, enabling them to effectively spread and level both materials.

Pros: Versatile, works with both asphalt and concrete.

Cons: May not be as effective as a rake specifically designed for concrete.

Therefore, the type of concrete rake chosen can significantly affect the efficiency and quality of a concrete job. Whether it’s the lightweight convenience of an aluminum concrete rake, the durability of a steel one, or the versatility of a concrete placer rake, understanding the different types of concrete rakes can help ensure that you have the right tool for the job. Remember to consider the needs of your specific project before choosing the most suitable rake.

4. How to choose the Right Concrete Rake

In the world of concrete work, choosing the right concrete rake is a decision that holds considerable weight. Given the variety of types, each catering to specific uses and projects, identifying the right one can seem like a daunting task. But fear not, in this guide, we’ll dive into the factors to consider when buying a concrete rake, and we’ll provide recommendations for different types of projects.

4.1 Factors to Consider When Buying a Concrete Rake

Before you start browsing online or head to your nearest hardware store, it’s essential to understand what factors should influence your decision. Here are some key considerations:

- Project Size and Type: The scale and type of your project play a significant role in determining the right concrete rake. For larger projects, you might need a rake with a wider head and longer handle, such as a landscape rake. Conversely, for smaller or more detailed work, a standard or placer concrete rake might be more suitable.

- Material: Concrete rakes come in different materials, such as steel, aluminum, and magnesium. Steel rakes are sturdy and can handle heavier loads but are more substantial. Aluminum and magnesium rakes are lighter and easier to handle, but they might not be as durable as their steel counterparts.

- Handle Length and Comfort: A comfortable handle can make the task of spreading and leveling concrete significantly easier. Look for rakes with ergonomic handles, and consider the length. Adjustable concrete rakes offer the flexibility of changing the handle length to suit your comfort.

- Finish: What kind of finish you want to achieve can influence the choice of your rake. If you’re looking for a textured finish, consider a landscape rake with rounded teeth. For a smooth finish, a roller rake might be a better option.

- Budget: Last but not least, consider your budget. More specialized rakes or those made from more durable materials might be more expensive. However, remember that a higher initial investment could result in a tool that lasts longer and performs better, saving you money in the long run.

4.2 Recommended Concrete Rakes for Different Types of Projects

Now that we’ve covered what to consider, let’s look at some recommended concrete rakes for different project types:

- General Purpose / Large Scale Projects: For general concrete jobs or larger scale projects, a standard concrete rake or a landscape rake is a good choice. These rakes are versatile and can handle a wide range of tasks. The Kraft Tool GG631 Heavy-Duty Concrete Rake is a great example of a durable, efficient standard concrete rake.

- Decorative Concrete Work: For decorative concrete work where a smooth finish is desired, a roller rake is the best choice. The MARSHALLTOWN Concrete Roller Screed can provide a superior smooth finish.

- Projects with Rebar or Mesh: If your project involves rebar or mesh, consider a concrete rake with a hook, like the Bon Tool 82-147 Concrete Placer Rake. The hook can pull these materials into position in the wet concrete, simplifying your work process.

- Smaller Projects or Detail Work: For smaller projects or detail work, a concrete placer rake or an adjustable rake could be ideal. They offer precision and flexibility, respectively. Consider options like the Midwest Rake Seymour Spiked Roller or the Kraft Tool CC944 19-1/2-Inch by 4-Inch Aluminum Gold Standard Concrete Placer.

By considering your specific project needs and the factors discussed above, you can make an informed decision when purchasing a concrete rake. Remember, the right rake can make your concrete work more efficient and yield better results, so take the time to choose wisely. From the various types of concrete rakes available to the particular uses of each, having a clear understanding will ensure you select the perfect tool for your project.

FAQ’s

What is a concrete rake used for?

A concrete rake is a specialized tool used in the construction industry for spreading, leveling, and finishing freshly poured concrete. It helps in ensuring an even surface and can also be used to create a desired texture on the concrete. The use of a concrete rake improves the efficiency and quality of concrete work.

How to choose the right type of concrete rake?

Choosing the right type of concrete rake depends on various factors such as the scale and type of your project, the material of the rake, the handle length and comfort, the desired finish, and your budget. For larger projects, a landscape or standard concrete rake is often suitable. For smaller, more detailed work, a placer or adjustable concrete rake could be ideal.

How do you use a concrete rake?

To use a concrete rake, first, prepare and pour your concrete mix onto the designated area. Place the rake into the mix and using a push-pull motion, spread the concrete evenly across the surface. Once the concrete is roughly spread, use the rake to level the surface by moving any excess concrete to areas where the layer is too thin. Depending on the desired finish, you might use different types of rakes or additional tools.

What are the different types of concrete rakes?

There are several types of concrete rakes designed for different tasks. The standard concrete rake is used for general concrete jobs, while the landscape rake is great for spreading and leveling tasks in larger areas. The placer rake is designed for detailed work and pulling mesh or rebar into position, and the roller rake is perfect for achieving a smooth finish. Other types include the aluminum, magnesium, and adjustable rakes.

Where can I buy a concrete rake?

Concrete rakes can be purchased from various sources. Physical stores like Lowe’s or Home Depot offer a variety of concrete rakes. Additionally, online marketplaces like Amazon provide an extensive selection of concrete rakes with user reviews, which can help guide your purchase decision. Remember to consider factors such as the type of rake, material, handle length, desired finish, and budget when making your choice.

How To Guide

How to Use a Concrete Rake: A Step by Step Guide

Step 1: Choose the Right Concrete Rake

The first step in using a concrete rake effectively is choosing the right type. This largely depends on the specific needs of your project. As discussed previously, there are several types of concrete rakes, including standard, aluminum, magnesium, steel, landscape, placer, hook, adjustable, roller, and asphalt/concrete rakes. Each type has its own pros and cons, so make sure to choose the one that suits your project best.

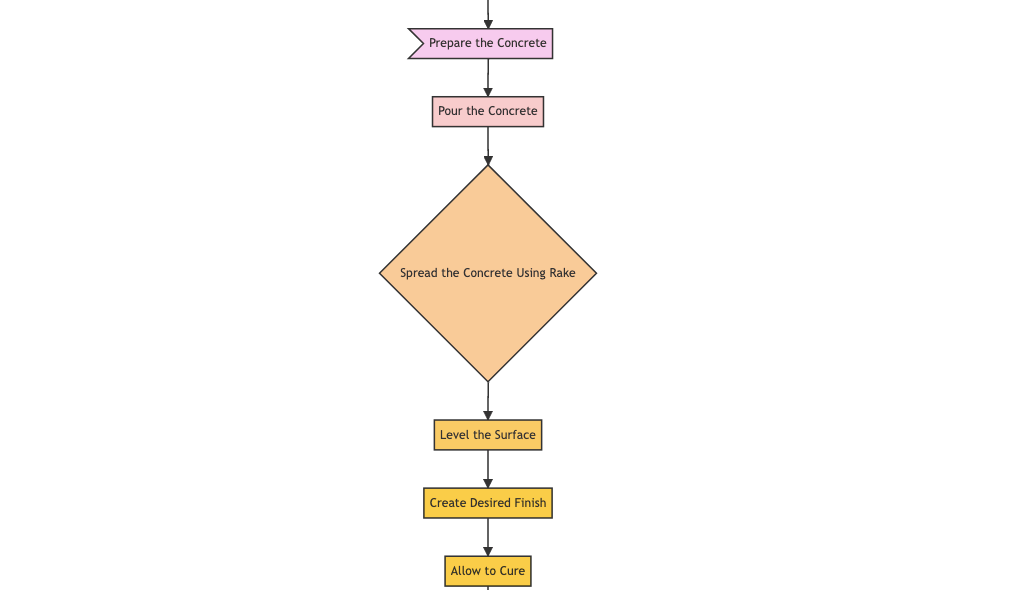

Step 2: Prepare the Concrete Mix

Once you have your rake, the next step is to prepare your concrete mix. Pour the mix into a large bucket or wheelbarrow and add water following the manufacturer’s instructions. Stir the mix thoroughly using a concrete mixer or a shovel until you achieve a uniform consistency. The right consistency should be similar to thick oatmeal.

Step 3: Pour the Concrete

Now, pour your concrete mix onto the designated area. You can do this directly from the bucket or wheelbarrow. Try to spread the mix roughly across the area using the bucket or wheelbarrow. However, don’t worry about getting it perfect at this point as the concrete rake will take care of the finer distribution.

Step 4: Spread the Concrete

Here’s where the concrete rake comes into play. Stand at the edge of the poured concrete. Place the rake into the mix, and using a push-pull motion, spread the concrete evenly across the surface. The technique is similar to raking leaves: you’ll pull the mix towards you, then push it away to spread it out.

Step 5: Level the Concrete

Once the concrete is roughly spread across the area, use the rake to level the surface. To do this, lightly pull the rake across the surface of the concrete, moving any excess concrete to areas where the layer is too thin. If you’re using a concrete placer rake, use the straight edge to screed or strike off the concrete for a level finish.

Step 6: Create the Desired Finish

Depending on your project, you may want to leave the concrete smooth or create a textured finish. If you’re aiming for a smooth finish, you can use a concrete float after raking. If you want a textured finish, a concrete landscape rake or a roller rake can create different textures.

Read More