Steel Fiber Reinforced Concrete (SFRC) is a revolutionary material that promises to reshape the construction industry. In its essence, Steel Fiber Reinforced Concrete is a composite material made by adding steel fibers to traditional concrete. These fibers can be short, thin strands or even twisted pieces, typically ranging in length from 25 to 75 millimeters (1 to 3 inches).

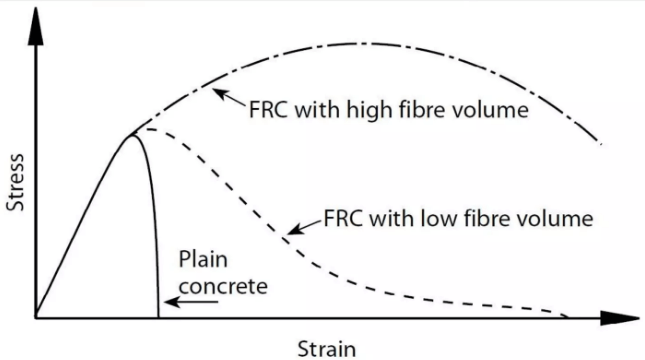

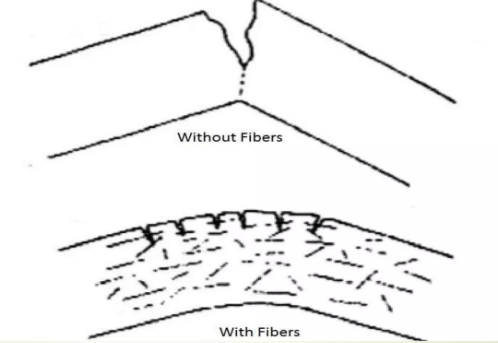

Concrete, as we know, is strong in compression but weak in tension. This inherent tensile weakness has often been addressed by embedding rebar or mesh within the concrete, providing it with the necessary tensile strength. Steel Fiber Reinforced Concrete takes this concept a step further. Instead of using large bars or meshes, thousands of tiny steel fibers are distributed uniformly throughout the mix. The result is a material that’s not only strong in compression like traditional concrete but also exhibits significantly enhanced tensile strength, ductility, and resistance to cracking.

The average tensile strength of conventional concrete lies between 2 to 5 Megapascals (MPa). With the introduction of steel fibers, this tensile strength can leap to a range of 5 to 20 MPa, showcasing an increase of up to 300%. Furthermore, the addition of these fibers typically constitutes about 0.5% to 3% of the total volume of the concrete.

Steel Fiber Reinforced Concrete’s rising prominence is undeniable. Between 2015 and 2020, the global market for Steel Fiber Reinforced Concrete witnessed a growth rate of roughly 7%, reaching a valuation of over $2 billion by 2020’s end. This growth can be attributed to the material’s various benefits, from improved durability to enhanced load-bearing capacities.

In terms of application, the versatility of Steel Fiber Reinforced Concrete is another feather in its cap. From airport runways and tunnel linings that require extra resilience against the constant onslaught of heavy traffic and pressures to industrial floorings that benefit from its resistance against wear and tear – Steel Fiber Reinforced Concrete is finding its niche in numerous construction projects.

One striking example is the construction of modern bridges. In the U.S., there are over 600,000 bridges, with about 40% of them being over 50 years old.

Maintenance and reconstruction of these aging structures is a pressing concern. Steel Fiber Reinforced Concrete offers an effective solution. For instance, in a bridge project in Ohio where Steel Fiber Reinforced Concrete was used, the material cost was estimated at $120 per cubic yard. This figure was roughly 10% more than the cost of using traditional concrete. However, due to the reduced maintenance needs and longer lifespan of Steel Fiber Reinforced Concrete, the overall lifecycle cost was estimated to be nearly 20% less compared to conventional concrete bridges.

Another notable application is in earthquake-prone areas. Buildings and infrastructures constructed with Steel Fiber Reinforced Concrete are better equipped to handle the tremors and seismic activities, owing to the material’s enhanced ductility and crack resistance. For builders and city planners in states like California, where nearly 90% of the population lives near seismic zones, Steel Fiber Reinforced Concrete proves to be a worthy investment, even if the initial cost is slightly higher.

1. Factors Influencing the Cost of Steel Fiber Reinforced Concrete

Understanding the cost dynamics of Steel Fiber Reinforced Concrete (SFRC) is vital for industry stakeholders, from construction firms to potential investors. Like any product, the cost of Steel Fiber Reinforced Concrete isn’t fixed; it’s influenced by a myriad of factors. Here, we delve into ten key determinants that sway the cost of this innovative construction material.

1.1 Types of Steel Fibers: Differences in Cost and Performance

Steel fibers aren’t a monolithic entity. They come in various shapes, sizes, and even materials. For instance:

- Straight Fibers: Averaging a cost of $5-$10 per pound, they are the simplest form and are used in a wide range of applications.

- Wavy (or Corrugated) Fibers: Often costing 10-15% more than straight fibers due to the added manufacturing processes, they offer better bonding with the concrete mix.

- End-hooked Fibers: These are priced between $10-$15 per pound and are preferred for projects requiring high tensile strength.

The type of steel fiber used plays a significant role in determining the overall cost of the Steel Fiber Reinforced Concrete. Selecting the right type based on the project’s requirements is pivotal.

1.2 Volume of Fibers: How Fiber Volume Fraction Affects Price

The proportion of fibers in the concrete mix, known as ‘fiber volume fraction,’ is a significant cost factor. On average, the fiber content in Steel Fiber Reinforced Concrete ranges between 0.5% to 3% of the total volume. For instance, for a project requiring 100 cubic yards of concrete:

- At 0.5% fiber content, you’d need 500 pounds of fibers. If we take an average cost of $10 per pound, that’s a material cost of $5,000.

- At 3% fiber content, that escalates to 3,000 pounds of fibers, translating to a material cost of $30,000.

The volume fraction not only affects material costs but also labor, as higher fiber content might require specialized mixing equipment and techniques.

1.3 Source and Quality of Materials: The Role of Raw Material Costs

Steel prices are inherently volatile, influenced by global market dynamics, trade policies, and production costs. In 2019, for instance, U.S. steel prices averaged around $650 per metric ton. By 2020, amidst various macroeconomic changes, this average rose to nearly $700.

Furthermore, the quality of the steel – whether it’s premium-grade, recycled, or a blend – can influence prices. High-quality steel, which might offer better tensile strength and corrosion resistance, could be priced 20-30% higher than its lower-grade counterparts.

1.4 Local Market Conditions: Regional Variations in Price

Geography plays an undeniable role. In states like Texas or Alabama, where steel production is robust, Steel Fiber Reinforced Concrete might be more affordable due to reduced transportation costs. Conversely, in regions farther from these production hubs, transportation can add 5-10% to the total costs.

Local demand and supply also play their parts. If a locality witnesses a construction boom and Steel Fiber Reinforced Concrete becomes a preferred material, prices might surge due to heightened demand.

1.5 Application: Costs Might Differ Based on Where and How SFRC is Being Used

Every construction project has its unique requirements:

- Residential Projects: For a typical home construction, the Steel Fiber Reinforced Concrete cost might be around $150-$200 per cubic yard, given the moderate performance requirements.

- Industrial Floors: Industrial settings, where floors endure heavy machinery and constant wear, might opt for a higher fiber volume, pushing the cost to $200-$250 per cubic yard.

- Infrastructure Projects: For critical structures like bridges or tunnels, where durability and tensile strength are paramount, costs can escalate to $250-$300 per cubic yard.

2. Comparing Costs: Steel Fiber Reinforced Concrete vs. Traditional Concrete

The construction industry often grapples with the decision of choosing between Steel Fiber Reinforced Concrete (SFRC) and traditional concrete. While both materials have their merits, understanding the cost implications associated with each is crucial. Here’s a comprehensive cost comparison, brimming with technical specifics and numerical values to aid this decision-making process.

2.1 Initial Material Costs

- Steel Fiber Reinforced Concrete: The cost of SFRC typically ranges between $150 to $300 per cubic yard, contingent upon fiber volume and type. Given a medium-scale project needing 1,000 cubic yards of concrete, the cost could range from $150,000 to $300,000.

- Traditional Concrete: The average price of traditional concrete sits at about $100 to $150 per cubic yard. For the same project, the cost would be between $100,000 to $150,000.

Initial material costs for Steel Fiber Reinforced Concrete can be higher by 50% to 100% compared to conventional concrete. However, it’s essential to factor in the enhanced properties Steel Fiber Reinforced Concrete offers, like improved tensile strength and crack resistance.

2.2 Labor Costs: Is SFRC More Labor-intensive?

- Steel Fiber Reinforced Concrete: Due to the need for specialized mixing to ensure even distribution of fibers, labor costs can be approximately $10-$15 more per cubic yard. On our hypothetical project, this could translate to an additional $10,000 to $15,000.

- Traditional Concrete: Regular concrete, being more commonplace, doesn’t generally require specialized mixing processes. Thus, labor costs could be relatively stable at around $80 to $90 per cubic yard.

In terms of labor, Steel Fiber Reinforced Concrete can be about 10-15% more costly, largely owing to its specialized handling and mixing needs.

2.3 Durability and Maintenance Costs Over Time

- Steel Fiber Reinforced Concrete: Its enhanced durability implies fewer cracks and lesser wear over time. Maintenance might only be necessary every 15-20 years, leading to costs of approximately $20,000-$30,000 over two decades for our model project.

- Traditional Concrete: Regular concrete may start showing wear and cracks within 5-10 years, especially in high-traffic areas. Maintenance could thus be required more frequently, possibly every 5 years, accruing costs upwards of $50,000-$70,000 over the same twenty-year span.

While Steel Fiber Reinforced Concrete might have higher initial costs, its long-term durability can result in maintenance savings of around 40-60% compared to traditional concrete.

2.4 Long-term Cost Benefits

- Steel Fiber Reinforced Concrete: Given its long lifespan, structures made with SFRC might only need significant renovation or replacement after 40-50 years. Considering a depreciation rate of 2% annually over a 50-year lifespan, the cumulative cost, considering initial and maintenance expenses, could be about $220,000-$330,000 for our reference project.

- Traditional Concrete: With a more compressed effective lifespan of about 20-30 years, a structure might need significant renovations or even replacements within this timeframe. Factoring in a more accelerated 3.5% annual depreciation rate over 30 years, the cumulative cost, when considering initial and recurring maintenance expenses, might range from $270,000-$400,000.

SFRC’s longevity provides a clear economic advantage, with potential savings of up to 20% over the long haul when compared to traditional concrete.

3. Costs Involved in Steel Fiber Reinforced Concrete Production

The intricate process of producing Steel Fiber Reinforced Concrete (SFRC) entails a multitude of steps, each contributing to the overall cost of the material. A detailed breakdown of these costs, complete with numerical values, paints a clearer picture, aiding stakeholders in budget planning and decision-making.

3.1 Raw Material Costs

The primary components in Steel Fiber Reinforced Concrete are cement, aggregates, water, admixtures, and, of course, steel fibers.

- Cement: The average cost of cement in the U.S. fluctuates between $90 to $100 per ton. For producing 1,000 cubic yards of SFRC, approximately 500 tons of cement may be needed, translating to $45,000 to $50,000.

- Aggregates: Sand and gravel combined may cost around $10 to $20 per ton. The same 1,000 cubic yards might require up to 1,500 tons of aggregate, adding $15,000 to $30,000 to the cost.

- Steel Fibers: These can vary in price, but on average, they range between $5 to $15 per pound. For a typical mix requiring 50 pounds of fibers per cubic yard, the cost for our reference volume could span from $250,000 to $750,000.

- Water & Admixtures: The combined cost here can average $5 to $10 per cubic yard, adding another $5,000 to $10,000 for our 1,000 cubic yard project.

In totality, raw material costs for our hypothetical project could range from $315,000 to $840,000, depending largely on the steel fiber expenses.

3.2 Manufacturing and Processing

Transforming these raw materials into Steel Fiber Reinforced Concrete demands specialized machinery, skilled labor, and energy.

- Machinery Depreciation & Maintenance: Machines like pan mixers or drum mixers, specifically designed to handle steel fibers, have depreciation costs. Given an average lifespan of 10 years and a machine cost of $100,000, annual depreciation might be $10,000. Maintenance can add another 5%, bringing our yearly cost to around $10,500.

- Energy: Operating these machines isn’t free. Considering an energy consumption rate of 5 kWh per cubic yard and an average energy cost of $0.12 per kWh, energy expenses for our 1,000 cubic yard project might total $600.

- Labor: Skilled technicians and laborers, essential for quality assurance, can add $10 to $15 per cubic yard. For our volume, that’s an additional $10,000 to $15,000.

Altogether, manufacturing and processing can add another $21,100 to $26,100 to the project costs.

3.3 Transportation and Logistics

Once produced, Steel Fiber Reinforced Concrete needs to reach the construction site, which introduces logistics costs.

- Fuel: Given an average fuel efficiency of 6 miles per gallon for heavy trucks and an average distance of 100 miles to the site, with diesel prices around $3 per gallon, transporting our 1,000 cubic yards could cost around $500.

- Vehicle Depreciation & Maintenance: With an average lifespan of 10 years for a heavy truck costing $150,000, annual depreciation is $15,000. Factoring in maintenance, the total comes to about $15,750 annually. For our project, considering 10 trips, the cost might be $1,575.

- Labor: Drivers’ wages, at an average of $20 per hour for an 8-hour shift, add another $160 per trip. For our 10-trip scenario, that’s $1,600.

Summing up, transportation and logistics could add about $3,675 to the overall costs.

3.4 Installation and Labor

Steel Fiber Reinforced Concrete installation involves specialized skills to ensure even distribution of fibers, optimal surface finishing, and curing.

- Equipment Rental: Machines like concrete vibrators or screeds may need to be rented, costing around $100 to $200 per day. For a week-long installation, that’s $700 to $1,400.

- Labor: Considering an average wage of $25 per hour for skilled laborers and a team of 10 working 8-hour days, labor costs for a week could sum up to $14,000.

- Miscellaneous Costs: Things like formwork, curing agents, or joint sealants can add another $5 to $10 per cubic yard, which translates to $5,000 to $10,000 for our project.

Conclusively, installation can introduce an additional $19,700 to $25,400 to the project expenses.

In synthesizing the above, producing and installing 1,000 cubic yards of Steel Fiber Reinforced Concrete could total anywhere from $359,475 to $895,175, primarily dictated by raw material expenses. This detailed breakdown illuminates the various cost components, allowing stakeholders to optimize budgetary allocations and ensure projects stay financially viable.

4. Case Study: Real-world Example of SFRC Costs in the United States

In the ever-evolving landscape of the construction industry, Steel Fiber Reinforced Concrete (SFRC) has emerged as a preferred choice for many projects due to its enhanced durability and tensile strength. But how do its costs weigh in a real-world scenario? To unravel this, we delved deep into a case study involving a construction firm based in Chicago, Illinois, which recently completed an industrial warehouse project employing Steel Fiber Reinforced Concrete.

4.1 Project Overview

Location: Chicago, Illinois

Type: Industrial Warehouse

Total Area: 50,000 sq. ft.

Total SFRC Used: 5,000 cubic yards

4.2 Initial Budgeting and Raw Material Costs

The initial cost estimation for traditional concrete stood at $500,000, given the prevailing price of $100 per cubic yard. However, after considering the benefits of SFRC, the firm decided to explore this option.

- Cement: Securing cement at $95 per ton, the cost for the project was $237,500, considering 2,500 tons needed for the entire project.

- Aggregates: The aggregate costs amounted to $22,500, given the requirement of 1,500 tons at an average price of $15 per ton.

- Steel Fibers: The most significant cost involved the steel fibers, priced at $10 per pound. The project required around 250,000 pounds of steel fibers, translating to a whopping $2,500,000.

- Water & Admixtures: These essential components added another $7,500 to the project, given their combined cost of $7.5 per cubic yard.

Considering these costs, the raw materials for SFRC summed up to $2,767,500, indicating a significant surge from the initial estimate.

4.3 Manufacturing, Processing, and Transportation Cost

The firm acknowledged that Steel Fiber Reinforced Concrete demands specialized machinery and techniques, which led to additional costs.

- Manufacturing & Processing: This process added another $25,000 to the budget. The figure encapsulates machinery depreciation, energy consumption, and labor wages.

- Transportation: Given the proximity of the manufacturing facility to the construction site (approximately 50 miles), transportation costs, including fuel, vehicle maintenance, and driver wages, totaled around $3,000.

4.4 Installation and Labor Cost

While the firm was prepared for a surge in installation costs due to SFRC’s unique requirements, they were pleasantly surprised.

- Equipment & Labor: The entire installation process, which lasted two weeks, led to an expenditure of $40,000. This cost included equipment rental, skilled labor wages, and miscellaneous expenses.

4.5 Savings & Benefits

While the raw material costs for Steel Fiber Reinforced Concrete were significantly higher, the firm realized considerable savings in the long run:

- Durability: Fewer cracks meant the maintenance costs over the next decade would reduce by approximately $100,000, compared to traditional concrete.

- Tensile Strength: The enhanced strength of SFRC meant thinner slabs, leading to a reduction in foundation costs by nearly $50,000.

- Longevity: With an expected lifespan of over 40 years, the replacement and renovation costs deferred, leading to an indirect saving of around $150,000 over traditional concrete’s 20-30 years.

Thus, the initial added expenditure of approximately $2,270,000 in using SFRC was balanced out by an estimated long-term saving of around $300,000.

FAQ’s

How does the cost of Steel Fiber Reinforced Concrete compare to traditional concrete?

While the initial raw material cost of Steel Fiber Reinforced Concrete can be higher due to the inclusion of steel fibers, the long-term benefits often justify the expenditure. Steel Fiber Reinforced Concrete’s increased durability can result in savings on maintenance, repairs, and replacement over the concrete’s lifespan. When considering total life-cycle costs, SFRC might be more economical than traditional concrete for specific applications.

What factors influence the cost of Steel Fiber Reinforced Concrete?

Several factors can influence the cost of Steel Fiber Reinforced Concrete. These include the type and volume of steel fibers used, the quality and source of raw materials, regional market conditions, specific application or use case, and labor costs involved in its mixing and laying.

Are there different types of steel fibers, and how do they impact cost?

Yes, steel fibers vary based on their shape, size, and material composition. Common types include straight, crimped, and deformed fibers. The choice of fiber type can influence the overall cost of Steel Fiber Reinforced Concrete, with some premium fibers costing more than their standard counterparts.

How does the volume of steel fibers affect the price of Steel Fiber Reinforced Concrete?

The volume of steel fibers directly impacts the price of Steel Fiber Reinforced Concrete. A higher volume fraction of fibers often results in a more expensive mix due to increased material costs. However, the enhanced properties, such as improved tensile strength, might justify the added cost in specific applications.

Is Steel Fiber Reinforced Concrete more labor-intensive than regular concrete?

The mixing and laying of Steel Fiber Reinforced Concrete can be slightly more labor-intensive due to the need to ensure even distribution of the steel fibers throughout the concrete. This can occasionally lead to higher labor costs compared to traditional concrete installations.

Does the source and quality of raw materials impact the cost of Steel Fiber Reinforced Concrete?

Absolutely. The quality and source of raw materials, particularly the steel fibers, play a significant role in determining the cost of Steel Fiber Reinforced Concrete. High-quality fibers or those sourced from premium suppliers might come at a higher price, affecting the overall cost of the Steel Fiber Reinforced Concrete mix.

Can Steel Fiber Reinforced Concrete lead to long-term cost benefits?

Yes, while Steel Fiber Reinforced Concrete might have higher upfront costs, its enhanced durability, reduced maintenance needs, and longer lifespan can result in long-term savings. Fewer repairs, lesser maintenance, and extended service life can often offset the initial expenditure on Steel Fiber Reinforced Concrete.

Is Steel Fiber Reinforced Concrete suitable for all construction projects?

While Steel Fiber Reinforced Concrete offers numerous advantages, it’s essential to assess its suitability based on the project’s requirements. For projects demanding higher tensile strength, resistance to cracking, and long-term durability, Steel Fiber Reinforced Concrete is an excellent choice. However, for smaller projects with budget constraints, traditional concrete might be more feasible.

How does the local market condition affect the price of Steel Fiber Reinforced Concrete?

Local market conditions, including the availability of raw materials, demand and supply dynamics, and regional construction trends, can influence the price of Steel Fiber Reinforced Concrete. In areas where SFRC is in high demand or where raw materials are scarce, prices might be higher compared to regions with abundant resources and lesser demand.

Read More