The allure of the St. Louis Gateway Arch, a monolithic masterpiece that soars 630 feet above the Mississippi River, lies not just in its stunning visual impact, but also in the depth of its architectural and engineering ingenuity. It is a towering tribute to human vision and creativity, a monument that not only celebrates the nation’s westward expansion but also showcases the remarkable strides made in the field of construction and design.

The Gateway Arch, standing tall on the riverfront of St. Louis, Missouri, is an extraordinary embodiment of the confluence of art, science, and technology. As the tallest man-made monument in the United States and a beloved symbol of the city of St. Louis, the Gateway Arch has drawn millions of people from around the globe since its completion in 1965. But beyond its outward spectacle and symbolic significance, there’s an array of fascinating design and construction facts that make the Gateway Arch a true marvel of modern engineering.

This comprehensive exploration aims to shed light on the top-100 construction and design facts about this iconic monument, delving deep into its genesis, structure, materials, and the technical prowess employed in its creation. The objective is to provide an in-depth perspective of the Gateway Arch to architects, engineers, construction enthusiasts, history buffs, students, or simply anyone fascinated by the wonders of architectural innovation and design.

The Gateway Arch, with its striking stainless-steel façade, towering presence, and elegant geometry, is not just an aesthetic wonder. It is a structural phenomenon. Every inch of the Arch tells a story of innovation, from its deep-set foundation and the steel-and-concrete superstructure to the mechanisms that transport visitors to its summit. By delving into these facts, we aim to bring you closer to understanding the vision, planning, and execution behind this monumental feat of engineering.

The monument’s architect, Eero Saarinen, conceived a structure that required groundbreaking construction techniques, complex mathematical calculations, and meticulous attention to detail. Despite his untimely death in 1961, Saarinen’s design was realized with unwavering dedication and precision, resulting in an iconic structure that continues to stand the test of time.

In this exploration, we will also reveal the type of foundation employed for the Arch, the depth at which it is set, the materials used, the role of dynamic loading in its design, and much more. From the Arch’s inception to its construction and the engineering challenges faced, this exposition presents an exhaustive account of what makes the Gateway Arch a living testament to human ingenuity and a symbol of American determination and resilience.

To fully appreciate the Gateway Arch is to understand its intricacies and the thoughtfulness that went into its design and construction. We will unravel the complexities and the peculiarities of its design, the codes adhered to, the type of soil present at the site, the economic implications, and even its lifespan predictions. We will delve into technical details such as the equivalent strength of the structure, the grade of concrete and steel used, the loading details, and other structural and engineering aspects.

We invite you to join us on this intriguing journey through the design and construction of the Gateway Arch. By doing so, we hope to provide you with a profound appreciation of this monumental structure and a deeper understanding of the complex interplay of architecture, engineering, and construction that has made it one of the most renowned landmarks in the world. Through this exploration, we aim to foster a dialogue about architectural innovation, inspire future engineers, architects, and builders, and illuminate the importance of design thinking and construction planning in shaping our built environment.

Each of the 100 facts shared here represents a piece of the puzzle that makes up the complete picture of the Gateway Arch’s awe-inspiring design and construction. By the end of this exploration, you will have a comprehensive understanding of why the Gateway Arch is much more than a monument; it is a remarkable testament to human innovation, ambition, and creativity. Let us embark on this insightful journey into the world of architecture and construction, as we uncover the top-100 construction and design facts of the Gateway Arch in St. Louis, MO.

Top-100 Facts of Gateway Arch in St. Louis

- The Gateway Arch, the tallest monument in the United States, is a masterpiece of modern architecture and engineering located in St. Louis, Missouri.

- The monument stands 630 feet high and 630 feet wide at its base, mirroring the shape of an inverted, weighted catenary curve.

- The total cost of construction was approximately $13 million, which in today’s dollars would be close to $100 million.

- Architect Eero Saarinen won a national design competition in 1947 to design the monument.

- The Gateway Arch was designed and constructed with the concept of celebrating the westward expansion of the United States.

- Its design consists of 142 individual stainless-steel sections, each being an equilateral triangle, which get smaller as they rise.

- The foundation type for the Gateway Arch is a deep foundation, employing the use of extensive piling.

- The depth of the foundation extends about 60 feet into the ground to bear the monumental load of the structure.

- The superstructure of the Arch is made of double-walled stainless-steel triangles filled with reinforced concrete from the base to 300 feet up.

- Above the 300-foot mark, the structure is hollow to the top.

- The primary materials used in the Arch’s construction are stainless steel and reinforced concrete.

- The Gateway Arch features a unique tram system to carry visitors to the observation deck at the top.

- A total of 900 tons of stainless steel was used to build the Gateway Arch, more than any other project in history at that time.

- In terms of equivalent strength, the Arch is designed to sway as much as 18 inches, and can withstand an earthquake.

- The structure was designed and built using many codes of the time, primarily the American Institute of Steel Construction (AISC) for the steelwork.

- The grade of steel used in the construction is Type 304 stainless steel.

- The concrete used is high-strength, with a yield strength of 9,000 psi.

- The economic analysis of the structure shows that it has been a major tourist attraction, bringing significant revenue to St. Louis each year.

- The expected lifespan of the structure is over a thousand years, demonstrating the durability and resilience of its design.

- The soil present at the site of the structure is primarily loam, ideal for its load-bearing capacity and minimal settlement.

- The Gateway Arch is designed to carry loads in compression, distributing the weight evenly through the arch and into the ground.

- For dynamic loading, the Arch can resist winds up to 150 miles per hour.

- The Gateway Arch is the centerpiece of the Jefferson National Expansion Memorial, which includes a museum about westward expansion.

- In terms of technical data, the surface area of the Arch is around 92,000 square feet, or about 2.4 acres.

- The Gateway Arch is a testament to American innovation, symbolizing the pioneering spirit of the nation’s early explorers and settlers.

- On a clear day, visitors can see up to 30 miles in each direction from the observation deck.

- Each leg of the Gateway Arch features an emergency staircase with 1,076 steps.

- A surprising fact is that no one died during the construction of the Gateway Arch, a rarity for such a massive project during its time.

- The Gateway Arch weighs 43,220 pounds, with the foundation bearing the majority of this weight.

- The structure was completed on October 28, 1965, after two and a half years of construction.

- Each leg of the Arch is embedded in 25,980 tons of concrete to stabilize the structure.

- Construction workers had to endure temperatures as high as 130 degrees Fahrenheit inside the steel sections during the summer.

- The unique stainless-steel skin reflects the changing moods of the sky, giving the Arch a dynamic appearance.

- The Arch sways a maximum of 9 inches (23 cm) in 150 mph (240 km/h) winds.

- Due to thermal expansion and contraction, the height of the Arch can vary by 2.5 cm.

- Despite the initial public controversy over its construction, the Arch has become an iconic symbol of St. Louis.

- An interesting fact is that Saarinen died before construction began and didn’t get to see his vision come to life.

- The interior of the Gateway Arch features a unique transportation system with small, egg-shaped capsules that carry visitors to the top.

- The base of each leg at ground level is 54 feet wide.

- The width between the legs at ground level is 630 feet, matching the overall height.

- Saarinen’s design was chosen from among 172 proposals in a competition to design a monument honoring westward expansion.

- The Arch was added to the National Register of Historic Places in 1987.

- The Gateway Arch is a symbol of the city of St. Louis, drawing millions of tourists each year.

- The structural system of the Arch can be classified as a non-building structure due to its unconventional shape and usage.

- The reinforced concrete in the Arch’s legs extends to 300 feet above the ground, with the rest being hollow stainless steel.

- Despite its height, the Gateway Arch doesn’t have any flat horizontal surfaces, all of them being curved.

- The design of the Arch was finalized using complex mathematical formulas to ensure structural stability.

- The foundation piles were driven to depths of 60 feet into bedrock, providing stability and resistance to seismic forces.

- The Arch’s design allows for movements caused by changes in temperature, wind, and even earthquakes.

- The triangular cross-section of the Arch, with its broad base tapering to a narrow top, provides inherent structural stability.

- The piling for the foundation was completed in 1961, taking just a few months to complete.

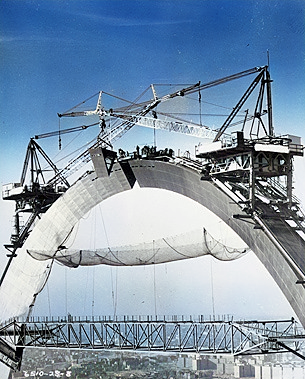

- Construction of the Gateway Arch required the use of a special crane, known as a “creeper crane,” which could move up and down the structure as it was being built.

- During construction, each triangular section was raised into place using hydraulic jacks, and then welded into place.

- To ensure the safety of workers, a safety net was hung between the legs of the arch during construction.

- The stainless steel for the Arch was supplied by the Pittsburgh-Des Moines Steel Company.

- The last piece of the Arch, known as the “keystone,” was put into place on October 28, 1965.

- The construction of the Gateway Arch was a major event in the history of St. Louis, drawing thousands of spectators.

- The Arch is resistant to corrosion due to its stainless steel surface, ensuring its longevity.

- Each triangular section of the Arch was filled with concrete after being put into place, adding strength and stability.

- Despite being completed over half a century ago, the Gateway Arch still holds several records for its design and construction.

- Construction of the Arch was financed by the federal government as part of a larger project to revitalize the St. Louis riverfront.

- The Arch was dedicated by Vice President Hubert Humphrey in May 1968, who hailed it as “a triumph of the imagination.”

- The observation deck at the top of the Arch can accommodate up to 160 people at a time.

- The unique tram system inside the Arch wasdesigned by Richard Bowser, an engineer who usually designed systems for transporting potato chips.

- The tram system consists of eight 5-passenger capsules in each leg, which rotate during the journey to keep the passengers upright.

- The foundation was designed to support the 43,220-ton weight of the Arch and resist wind pressures.

- The construction of the Arch was a joint venture between two companies, MacDonald Construction Co. of St. Louis and the American Bridge Division of the U.S. Steel Corporation.

- The final cost of the Gateway Arch was almost triple the original budget, primarily due to inflation and modifications to the design.

- While the Arch appears symmetrical, the south leg was built slightly differently due to a minor error during construction.

- During its 50th anniversary in 2015, the Arch underwent a massive renovation project to upgrade the visitor center and museum.

- The Gateway Arch was the first monument in the U.S. to have its own wireless data system, installed in 2014.

- The Arch’s foundation features a complex system of tension and compression members to balance the loads.

- Despite its size, the Arch was designed to be lightweight, with a hollow structure that reduces weight while maintaining strength.

- The weight of the Arch is evenly distributed between its two legs, which are firmly anchored in the bedrock.

- The interior of the Arch features a system of steel stairs, elevators, and trams to facilitate movement.

- An interesting fact is that despite its towering height, the Arch only covers a ground area of about one acre.

- The stainless steel used in the Arch was chosen for its durability and reflective properties, which give the monument its gleaming appearance.

- At the time of its completion, the Arch was one of the top five tallest structures in the world.

- The construction of the Arch marked a significant technological achievement, utilizing cutting-edge construction techniques of the time.

- Due to its height and location near the Mississippi River, the Arch has been struck by lightning numerous times.

- Despite the Arch’s graceful curve, each segment is straight – the illusion of a curve is created by arranging the segments at precisely calculated angles.

- During construction, the margin of error for placing each section was less than half a millimeter.

- Saarinen’s design was initially criticized as being too futuristic, but it has since been hailed as a masterpiece of modern architecture.

- The Arch’s unique shape and structure required the development of custom tools and equipment for its construction.

- Despite the complex design, the Arch was completed without any major mishaps or accidents.

- A biographical film about Saarinen, titled “The Gateway Arch: A Reflection of America,” was released in 2006.

- The concrete in the legs of the Arch was poured in a continuous stream to ensure consistency and strength.

- The “topping out” ceremony for the Arch, when the final piece was placed, was broadcasted live on national television.

- The stainless steel for the Arch was produced using a special process to enhance its durability and resistance to weathering.

- The soil around the Arch was landscaped to form a park, offering a picturesque setting for this monumental structure.

- The Arch’s foundation was designed to withstand a variety of natural disasters, including floods, earthquakes, and tornadoes.

- Despite its massive size, the Arch has a surprisingly slender profile, measuring just 54 feet at its widest point.

- The Arch’s sleek design and reflective surface make it a perfect subject for photographers.

- The interior of the Arch is illuminated at night, providing a dramatic view of the city below.

- The Gateway Arch was the first man-made monument in the U.S. to be taller than the Washington Monument.

- The construction of the Arch required the demolition of 40 city blocks in downtown St. Louis.

- The Arch is often used as a symbol of St. Louis, appearing on the city’s flag and other official documents.

- The Gateway Arch was the first national monument to be designed through a competitive process.

- The tram ride to the top of the Arch takes four minutes, offering visitors a panoramic view of the St. Louis skyline.

- Despite its monumental size, the Gateway Arch is so well-balanced that it can sway in the wind without any structural risk.

FAQ’s

How tall is the Gateway Arch in St. Louis, MO?

The Gateway Arch in St. Louis, Missouri is a stunning 630 feet (192 meters) tall. It’s the tallest man-made monument in the United States, and it stands as a testament to the westward.

Who designed the Gateway Arch?

The iconic Gateway Arch was designed by Finnish-American architect Eero Saarinen. He won the design competition for the monument in 1947.

What materials were used to construct the Gateway Arch?

The primary materials used in the construction of the Gateway Arch were stainless steel and reinforced concrete. The outer skin is composed of a stainless-steel alloy, while the inner skin consists of reinforced carbon steel.

How was the Gateway Arch constructed?

The construction of the Gateway Arch involved a series of complex steps. It was built from the ground up, with triangular sections being incrementally added. The sections were raised with a system of cranes and derricks and then carefully put into place.

When was the Gateway Arch completed?

The Gateway Arch was completed on October 28, 1965, after two and a half years of construction.

What is the foundation depth of the Gateway Arch?

The foundation of the Gateway Arch is set 60 feet into the bedrock. This depth was necessary to ensure the stability of the monument due to its significant height.

How much did it cost to build the Gateway Arch?

The total cost of the Gateway Arch construction was around $13 million. This was much higher than the initial budget, mainly due to inflation and modifications to the design.

What kind of load does the Gateway Arch structure handle?

The Gateway Arch has been designed to withstand substantial wind loads, and its weight is evenly distributed between its two legs. The structure is designed to sway up to 18 inches in a 150 mph wind, with the center of gravity shifting only one inch.

How long is the lifespan of the Gateway Arch?

While there is no precise estimate of the Gateway Arch’s lifespan, its robust construction and the use of durable materials suggest that it could stand for hundreds, if not thousands of years with proper maintenance.

What type of soil is present at the Gateway Arch construction site?

The construction site of the Gateway Arch features loess soil, which is silt-sized sediment formed by the accumulation of wind-blown dust. The soil composition was taken into account during the design and construction of the monument’s foundation.

Read More

2 thoughts on “Gateway Arch : Top-100 Construction and Design Facts”