Polychlorinated Biphenyls (PCBs) are a group of man-made organic chemicals that gained industrial prominence due to their unique chemical properties. They were commercially manufactured and extensively used in electrical, heat transfer, and hydraulic equipment from the late 1920s until their production was banned in the U.S. in 1979 due to their harmful environmental and health effects. They’re chemically stable, non-flammable, and demonstrate high boiling points, all properties that made them ideal for various industrial and commercial applications.

PCBs are highly persistent in the environment and resist breaking down, even under extreme temperature and pH conditions. They can exist in the air, water, and soil for extended periods, and this has contributed to their widespread distribution worldwide. Due to their low water solubility and high fat solubility, they tend to accumulate in the fatty tissues of living organisms, a phenomenon known as bioaccumulation. They are easily transferred up the food chain, thus posing significant ecological risks.

PCBs are classified as probable human carcinogens by the U.S. Environmental Protection Agency (EPA), and numerous studies have linked them with a variety of adverse health effects. These range from problems in the immune, reproductive, nervous, and endocrine systems to more serious conditions like cancer. Moreover, PCBs have been found to negatively impact fish, birds, and other wildlife, affecting their reproduction, growth, and development.

The widespread contamination of soils and aquifers with PCBs presents an urgent environmental and public health problem. PCBs enter soils and aquifers through various channels, including improper disposal of PCB-containing equipment and materials, leaks or spills from transformers or capacitors, and deposition from the atmosphere. Soils and aquifers, particularly in urban and industrial areas, can harbor high concentrations of PCBs, posing severe threats to ecosystems and human health.

The remediation of Polychlorinated Biphenyls from soils and aquifers is a complex process but is of utmost importance. It’s not only crucial to protect the environment and biodiversity but also to safeguard human health. In the context of soil, PCB remediation ensures the health of the soil, making it fit for plant life and preventing the seepage of toxins into groundwater or crops. For aquifers, remediation safeguards water quality, a crucial aspect as many communities around the world rely heavily on groundwater for their drinking and irrigation needs.

Mitigating PCB contamination is also essential from an economic standpoint. Contaminated sites can lead to property value depreciation, while cleanup and legal liabilities can be costly. Importantly, effectively remediating PCBs from soils and aquifers can prevent potential adverse health outcomes, reducing healthcare costs.

Effective remediation of Polychlorinated Biphenyls requires the concerted efforts of governments, environmental bodies, and researchers worldwide. Through continued investment in research, development, and implementation of effective remediation technologies, we can move toward a safer, healthier world.

This article will explore the challenges and solutions associated with PCB remediation in soils and aquifers, delving into the technical intricacies of various remediation strategies, and illuminating the path toward effective environmental restoration.

1.Background of Polychlorinated biphenyls (PCBs) Contamination

Polychlorinated Biphenyls, or PCBs, were first synthesized in the late 19th century, but their large-scale production did not commence until 1929. Manufactured by the Swann Chemical Company, later acquired by Monsanto, PCBs became widely used due to their chemical stability, electrical insulating properties, flame resistance, and low volatility. This vast array of beneficial properties led to their application in a wide variety of products, including electrical transformers and capacitors, hydraulic fluids, lubricants, plasticizers, and other industrial chemicals.

However, the appealing attributes of PCBs that led to their widespread use are the same attributes that make them so problematic from an environmental standpoint. Their chemical stability, coupled with a propensity to adhere to organic particles, allows them to persist in the environment for extended periods.

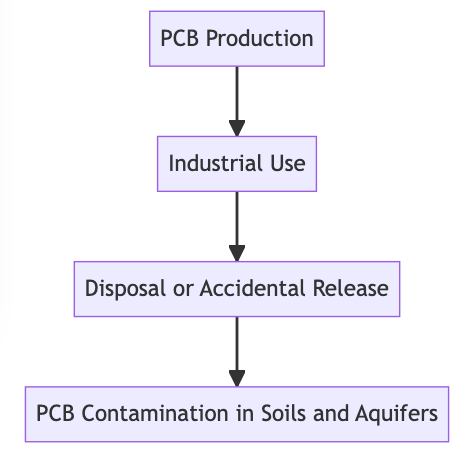

PCBs primarily end up in soils and aquifers through both deliberate and accidental releases. Industrial processes, illegal dumping, and improper disposal of PCB-containing materials have led to soil contamination. Moreover, PCBs can attach to dust and other airborne particulates, which eventually settle on the soil surface. Over time, these particles can infiltrate the soil profile, increasing the concentration of PCBs in the soil.

Aquifer contamination is also a concern. PCBs can percolate through the soil, especially in instances where they are dissolved or suspended in other liquids, such as in the case of leaks or spills. Furthermore, PCBs can enter aquifers via leaching from contaminated soils or from the bottom sediment of polluted water bodies.

The environmental and human health impacts of PCB contamination are significant and well-documented. From an environmental perspective, PCBs pose a threat to wildlife. Aquatic organisms are particularly vulnerable as PCBs can accumulate in the fatty tissues of fish and other aquatic life, leading to developmental issues, reproductive failure, and population declines. Similarly, terrestrial wildlife can ingest PCBs through contaminated food or water sources, resulting in similar adverse effects.

From a human health perspective, the dangers of PCB exposure are well established. According to the U.S. Environmental Protection Agency (EPA) and the International Agency for Research on Cancer (IARC), PCBs are classified as probable human carcinogens. Long-term exposure to PCBs can lead to cancer and a plethora of other health problems such as issues with the immune, reproductive, nervous, and endocrine systems. Of particular concern is the potential for bioaccumulation and biomagnification of PCBs in the food chain, potentially impacting human health even at low levels of environmental contamination.

Evaluating the historical context of PCB production and usage, alongside the understanding of how they infiltrate our soils and aquifers, underscores the immense importance of remediation efforts. The consequences of PCB contamination extend far beyond localized ecological harm, presenting a significant challenge to global health and environmental sustainability. Effective remediation strategies are not just important, they are vital for the well-being of our planet and its inhabitants. In the following sections, we will delve into the current standards for PCB remediation, detection methods, and the latest advancements in remediation techniques.

2. Current Standards for Polychlorinated biphenyls (PCBs) Remediation

Managing and mitigating PCB contamination in the environment is regulated by several national and international guidelines. In the United States, the Environmental Protection Agency (EPA) oversees these regulations, with the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) and the Toxic Substances Control Act (TSCA) serving as the primary governing laws.

The EPA has established remediation goals (RGs) for PCBs in soil, which serve as cleanup targets during the remediation process. These levels vary based on the use of the land in question. For instance, for residential areas, the EPA recommends a cleanup level of 1 milligram of PCBs per kilogram of soil (mg/kg), while industrial areas have a higher allowable limit of 25 mg/kg, given that direct human contact is likely to be less frequent in these areas.

As for water bodies, the EPA, under the Clean Water Act, has set the maximum contaminant level (MCL) for PCBs at 0.0005 milligrams per liter (mg/L). This applies to all water bodies serving as a source of drinking water. Additionally, there are also guidelines established for the protection of aquatic life.

On the international front, the Stockholm Convention on Persistent Organic Pollutants, an international environmental treaty, addresses PCBs among other pollutants. The treaty, ratified by over 180 countries, aims to eliminate or restrict the production and use of persistent organic pollutants, including PCBs. However, it’s important to note that each country enforces its own specific standards, which often align with or are stricter than those set by the Stockholm Convention.

While these guidelines and standards serve as crucial tools in managing PCB contamination, numerous challenges exist in ensuring compliance and reaching the set targets. The most apparent issue is the technical difficulty of PCB remediation. Because PCBs are chemically stable and bind strongly to soil and sediment particles, they’re resistant to traditional remediation methods.

Moreover, disparities exist in the global capacity for PCB management. Developed nations generally have better resources and infrastructure to handle PCB remediation, while developing nations often face hurdles such as inadequate technology, lack of technical expertise, and insufficient financial resources.

There’s also the issue of “orphan” PCB sources. These are cases where PCB-containing equipment or materials have been abandoned or their ownership cannot be determined. The remediation of these sites can be complex, particularly in establishing who is responsible for the cleanup.

Ensuring effective PCB remediation is a challenging task requiring the concerted efforts of various stakeholders, including regulatory agencies, environmental professionals, industry players, and the general public. Further research and development are essential to devise more effective and cost-efficient remediation methods. Public awareness and education can also go a long way in ensuring proper handling and disposal of PCB-containing materials, thereby preventing further contamination.

3. Methods of Detecting Polychlorinated biphenyls (PCBs) in Soils and Aquifers

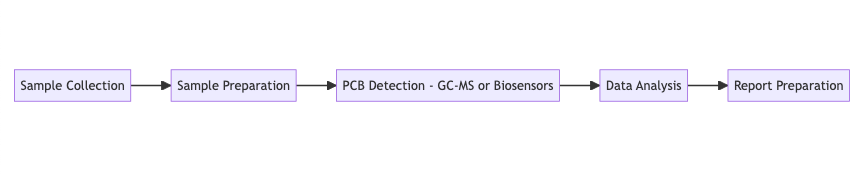

Given the persistent nature and the associated health and environmental hazards of Polychlorinated Biphenyls (PCBs), accurate and efficient detection methods are crucial in facilitating effective remediation strategies. Let’s explore some of the common and emerging methods used for detecting PCB contamination in soils and aquifers.

3.1 Gas Chromatography (GC)

One of the most commonly used methods for PCB detection in both soils and water is gas chromatography, often coupled with mass spectrometry (GC-MS) or an electron capture detector (GC-ECD). This technique involves extracting the PCBs from a sample, and then separating, identifying, and quantifying them. GC is known for its high precision and sensitivity, making it a powerful tool for PCB detection.

3.2 Immunoassay techniques

These techniques use the antibody-antigen reaction to detect PCBs. Immunoassays can provide rapid, on-site screening of soil and water samples, offering a significant advantage when immediate results are required. Enzyme-Linked Immunosorbent Assay (ELISA) is a typical example of immunoassay used for detecting PCBs.

3.3 Biosensors

An emerging field in PCB detection is the use of biosensors. These devices combine a biological component, such as a microorganism or enzyme that can interact with PCBs, with a physicochemical detector component. This technology can potentially offer real-time, on-site detection, which is beneficial for ongoing monitoring of a site.

Each method comes with its own set of advantages and disadvantages. For example, gas chromatography methods are highly sensitive and can provide precise measurements, but they are time-consuming, costly, and require a well-equipped laboratory and trained technicians. On the other hand, immunoassays and biosensors offer quicker, on-site detection, but they may lack the same level of accuracy as GC methods, especially for complex mixtures or low concentration samples.

Real-world applications of these techniques abound. For instance, a 2019 study used GC-MS to detect PCBs in soils around a former e-waste recycling site in Northern Vietnam. The researchers were able to identify high levels of PCB contamination, providing crucial data for remediation planning.

Similarly, the use of immunoassay kits for rapid on-site PCB detection has been documented in various environmental monitoring projects. The EPA’s Superfund program, for instance, has successfully used immunoassay kits for preliminary site assessments.

Emerging technologies like biosensors are showing promise in laboratory settings. In a study published in the journal Chemosensors, researchers successfully used a biosensor incorporating genetically engineered bacteria to detect PCBs in water samples. While such technology is still in its early stages of development, it highlights the potential for innovative solutions in PCB detection.

Accurate detection and quantification of PCBs in soils and aquifers is the first step in any successful remediation strategy. As technology advances, we can expect the development of more sophisticated, accurate, and efficient methods for PCB detection. Such developments will be crucial in our ongoing efforts to manage and mitigate the risks associated with PCB contamination. In the next section, we’ll delve into the techniques for remediation of PCBs in soils and aquifers.

4. Techniques for Remediation of Polychlorinated biphenyls (PCBs) in Soils

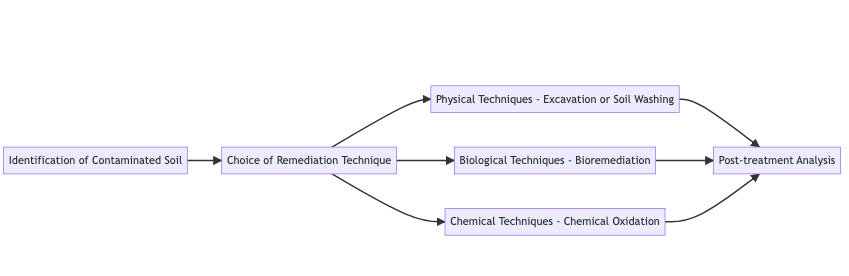

The remediation of Polychlorinated Biphenyls (PCBs) in soils is a challenging task given the persistent nature of these compounds. Yet, several methods have shown promise. Here we’ll explore some of the most notable techniques, including bioremediation, soil washing, and thermal desorption.

4.1 Bioremediation:

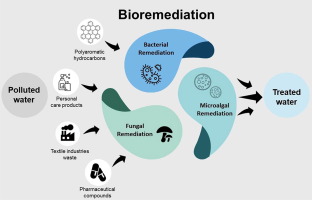

This eco-friendly method utilizes living organisms, primarily microorganisms like bacteria and fungi, to degrade contaminants. Bioremediation can take several forms, but the two most common for PCBs are bio-augmentation and bio-stimulation. Bio-augmentation involves the introduction of PCB-degrading microorganisms into the contaminated soil, while bio-stimulation enhances the activity of existing PCB-degrading microorganisms by providing nutrients or altering environmental conditions. Bioremediation can be cost-effective and doesn’t require soil excavation, reducing secondary pollution.

However, the effectiveness of bioremediation can be influenced by many factors such as the type and concentration of PCBs, soil properties, and environmental conditions. It is also a slow process, often taking months to years to achieve desirable results. Moreover, complete mineralization of PCBs is challenging, with lesser-chlorinated byproducts often remaining in the soil.

4.2 Soil Washing:

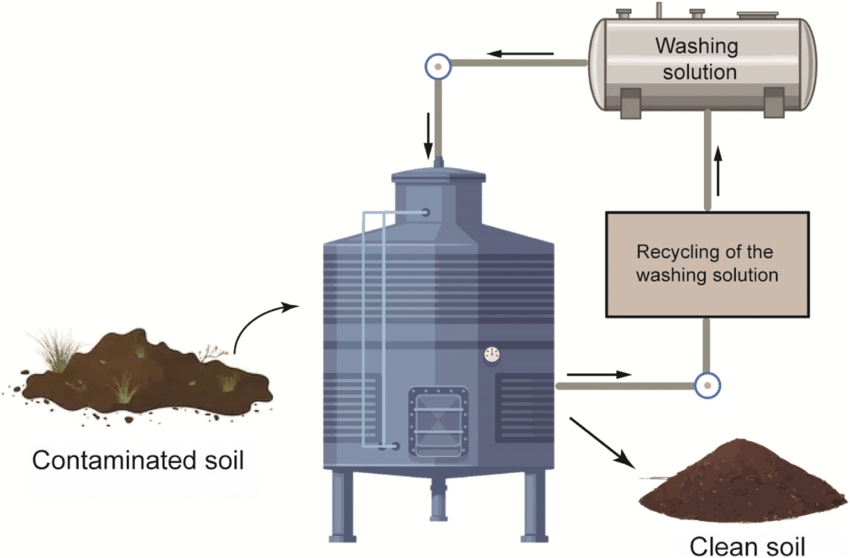

Soil washing involves physically removing PCBs from soil using water, often in combination with chemical additives or surfactants to enhance solubility. The process can remove a high percentage of PCBs, especially from sandy soils with low organic content.

However, soil washing is less effective for clay or organic-rich soils where PCBs are strongly adsorbed. It also generates a wastewater stream that needs further treatment. As for cost, soil washing can be expensive, particularly for large contaminated sites. It typically requires off-site treatment, meaning the soil needs to be excavated and transported, increasing the project’s complexity, timeframe, and cost.

4.3 Thermal Desorption

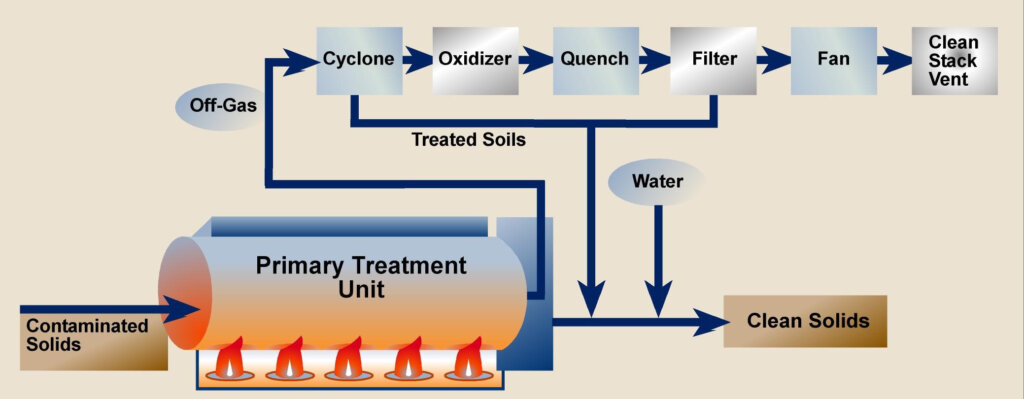

This technique involves heating the soil to evaporate PCBs, then capturing the vapors and treating them separately. Thermal desorption can be very effective, capable of treating a wide range of PCB concentrations and applicable to various soil types.

Despite its effectiveness, thermal desorption has a few downsides. First, it’s typically more costly than other remediation methods due to the energy-intensive nature of the process. Second, it requires soil excavation and off-site treatment in most cases. Lastly, the treatment of the PCB-laden vapors poses additional technical challenges.

In the context of a real-world application, the Hunters Point Naval Shipyard in San Francisco employed a combination of techniques, including bioremediation and thermal desorption, to remediate PCB-contaminated soils. Each method was chosen based on its appropriateness for the specific conditions of the site and the type of soil contamination.

The decision of which remediation method to use often depends on several factors, including the extent and type of contamination, soil properties, available budget, and regulatory requirements. A site-specific risk assessment is usually carried out to determine the most suitable remediation strategy. As technology and our understanding of PCB behavior in the environment advance, we can look forward to more efficient and cost-effective solutions to the problem of PCB contamination in soils.

5. Techniques for Remediation of Polychlorinated biphenyls (PCBs) in Aquifers

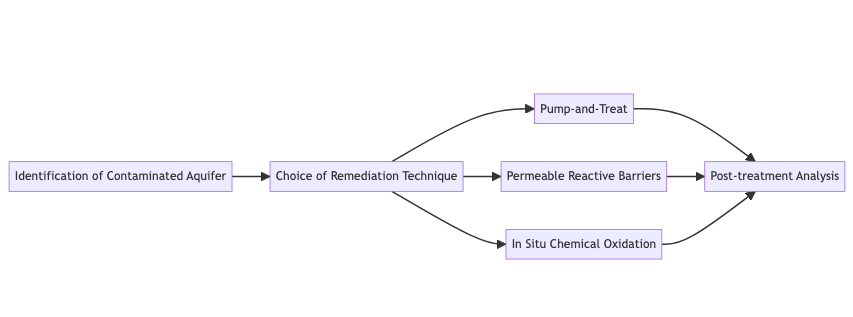

Aquifers, serving as crucial reservoirs of fresh water, can become hotspots for PCB contamination due to the chemical’s persistence and mobility. Several remediation techniques have shown promise in cleaning up PCB-contaminated aquifers. Here, we will delve into three notable methods: pump-and-treat, permeable reactive barriers, and in situ chemical oxidation.

5.1 Pump-and-Treat

This is the most traditional technique and involves extracting groundwater from the aquifer via wells and treating it on the surface to remove PCBs. The clean water is then either discharged or reinjected into the ground.

The pump-and-treat method is effective in reducing the mass of PCBs in the aquifer and preventing the further spread of contamination. It is relatively simple to operate and manage, and it is suitable for a wide range of contamination conditions.

However, this method has several limitations. It’s typically slow and can take many years or even decades to clean up a highly contaminated site. The extraction of groundwater can also lead to undesirable subsurface changes, such as land subsidence. Lastly, treating the extracted groundwater, particularly if it contains high PCB concentrations, can be technically challenging and costly.

5.2 Permeable Reactive Barriers (PRBs)

A PRB is an underground wall made of reactive material that treats contaminated groundwater in situ as it flows through the barrier. For PCB contamination, zero-valent iron (ZVI) or activated carbon can be used as the reactive material, which can adsorb or degrade PCBs.

PRBs offer several advantages. They provide passive, long-term treatment without the need for constant energy input or maintenance. They also prevent the spread of contamination downstream and don’t require the extraction and disposal of groundwater, making them more environmentally friendly.

However, the installation of PRBs can be complex and costly, especially for deep aquifers. The effectiveness of PRBs can also be limited by the flow rate and direction of groundwater and the types and concentrations of PCBs present.

5.3 In Situ Chemical Oxidation (ISCO)

This method involves injecting chemical oxidants into the aquifer to break down PCBs. Common oxidants used include hydrogen peroxide, persulfates, and permanganates.

ISCO can rapidly reduce PCB concentrations and doesn’t require the extraction of groundwater, reducing secondary waste. However, it can potentially alter subsurface properties and affect groundwater quality due to the residual chemicals. It can also be challenging to distribute the oxidants uniformly across the contamination zone.

Comparatively, real-world applications of these techniques vary. For instance, the pump-and-treat method has been widely used in the Superfund sites across the United States. PRBs have been installed at several sites in Europe and North America to treat various organic contaminants, including PCBs. ISCO, on the other hand, has been more commonly used for other contaminants, such as chlorinated solvents, but it shows promise for PCBs as well.

Choosing the most suitable remediation technique often involves a detailed analysis of site-specific conditions, including the geology, hydrology, type and extent of contamination, regulatory requirements, and cost considerations. As with soil remediation, continued research and technological advancement are essential to improve the efficiency, effectiveness, and sustainability of these techniques.

6. Case Studies of Successful Polychlorinated biphenyls (PCBs) Remediation

The global presence and persistent nature of PCB contamination have led to the development and execution of numerous remediation strategies around the world. Studying these instances of successful PCB remediation provides valuable insights into the challenges faced, solutions implemented, and the long-term impacts on local environments. Here, we will delve into a few notable case studies of successful PCB remediation.

6.1 Case Study : Fox River, Wisconsin, USA

The remediation of the Fox River in Wisconsin represents one of the largest and most expensive PCB cleanup projects in the world. During the 1950s and 1960s, paper mills along the river had released large amounts of PCBs into the water, leading to widespread contamination of the river sediment and posing significant risks to human health and wildlife.

The remediation plan, initiated in the early 2000s, involved a combination of dredging and capping techniques. Dredging was used to physically remove the contaminated sediment, while capping involved covering the remaining contaminated sediment with clean material to prevent PCB migration. A total of 3.9 million cubic yards of contaminated sediment was removed, and over 460 acres of the river bed were capped.

This massive project, completed in 2015, was successful in significantly reducing PCB levels in the river. Post-remediation monitoring has shown a notable decrease in PCB concentrations in water, fish, and wildlife, demonstrating the project’s long-term effectiveness. This case highlights the effectiveness of physical removal techniques, although they are labor-intensive and expensive.

6.2 Case Study : Hunters Point Naval Shipyard, San Francisco, USA

At the former Hunters Point Naval Shipyard in San Francisco, a combination of techniques was employed to remediate PCB-contaminated soils. The remediation strategy involved excavation, off-site disposal, bioremediation, and thermal desorption. Bioremediation involved the use of bacteria to break down the PCBs, while thermal desorption used heat to remove PCBs from the soil.

The multi-faceted approach allowed for the treatment of different types and levels of contamination across the site. The remediation project, completed in the early 2010s, was successful in meeting cleanup goals and preparing the site for redevelopment. This case showcases the advantages of utilizing a combination of remediation techniques based on site-specific conditions.

6.3 Case Study : Jiujiang, China

In Jiujiang, China, a novel method called subcritical water extraction (SCWE) was employed to remediate PCB-contaminated soils. SCWE uses water at high temperatures and pressures to extract contaminants from the soil. This method was combined with a chemical reducer (sodium borohydride) to enhance the degradation of PCBs.

The project, completed in 2015, achieved a high remediation efficiency, reducing the total PCB concentration in the soil by over 90%. This case demonstrates the potential of emerging remediation techniques and the importance of continued research and innovation in the field of PCB remediation.

6.4 Case Study : Brockovich Aquifer, Australia

In Australia, the remediation of a PCB-contaminated aquifer was achieved using a permeable reactive barrier (PRB) filled with activated carbon. The PRB treated the contaminated groundwater in situ as it flowed through the barrier, adsorbing the PCBs onto the activated carbon.

Completed in the early 2020s, this project was successful in reducing PCB concentrations in the groundwater to below regulatory limits. Long-term monitoring has confirmed the continued effectiveness of the PRB, highlighting the potential of this passive, in situ treatment method for groundwater remediation.

These case studies provide valuable insights into the real-world application of various PCB remediation techniques. They demonstrate the importance of a site-specific approach, considering factors such as the type and level of contamination, local geology, and available resources

7. Future of Polychlorinated biphenyls (PCBs) Remediation

As we continue to grapple with the global problem of Polychlorinated Biphenyls (PCBs) contamination, the future of PCB remediation looks toward the development of more efficient, cost-effective, and environmentally friendly solutions. This necessitates harnessing the power of technology and innovation.

First and foremost, the future of PCB remediation will undoubtedly involve further advancements in biotechnology. The use of specially engineered microorganisms or enzymes to break down PCBs offers an eco-friendly and potentially cost-effective alternative to traditional remediation methods. Through genetic engineering, researchers are aiming to enhance the PCB-degrading capabilities of these bio-agents and to broaden the range of conditions under which they can effectively function.

Nanotechnology also holds great promise in this field. Nanoscale zero-valent iron (nZVI), for example, has been extensively studied for its potential in treating PCB contamination. Due to its small size, high reactivity, and large surface area, nZVI can enhance the degradation of PCBs in soils and aquifers. Research is ongoing to optimize the delivery and stability of nZVI and other nanoparticles in the environment.

Furthermore, the use of advanced materials in remediation techniques is a rapidly developing area. One exciting advancement is the use of biochar, a carbon-rich material derived from the pyrolysis of biomass. Biochar has been shown to effectively adsorb PCBs in soils and sediments due to its large surface area and porous structure. Researchers are exploring ways to modify biochar to enhance its PCB adsorption capacity and selectivity.

In the realm of groundwater remediation, the concept of self-sustaining treatment for active remediation (STAR) is being explored. This method involves the controlled injection of air into the subsurface to stimulate the smoldering combustion of contaminants, including PCBs. The heat generated from this process can effectively destroy the PCBs in situ.

Moreover, the integration of remediation techniques, or the so-called “treatment trains,” is expected to gain more attention in the future. This approach involves the sequential application of different remediation methods to achieve more comprehensive and efficient treatment. For instance, soil washing can be used to remove a large fraction of PCBs from soil, followed by bioremediation to treat the remaining, more strongly adsorbed PCBs.

Beyond technological advancements, the future of PCB remediation also lies in improving our understanding of the fate and behavior of PCBs in the environment. More research is needed to elucidate how PCBs interact with different soil and aquifer materials, how they transform under various environmental conditions, and how these processes can be leveraged for more effective remediation.

Lastly, the successful implementation of PCB remediation strategies in the future will depend on continued collaboration among scientists, engineers, policy makers, and community stakeholders. Efforts should be made to increase public awareness and education about PCB contamination and remediation, and to involve local communities in decision-making processes related to remediation projects.

FAQ’s

What are Polychlorinated biphenyls (PCBs)?

Polychlorinated biphenyls (PCBs) are man-made organic compounds that were widely used in various industrial applications due to their chemical stability, insulating properties, and non-flammability. However, due to their environmental persistence and potential health risks, the production of PCBs was banned in the late 1970s in many countries.

Why is remediation of Polychlorinated biphenyls (PCBs) in soils and aquifers necessary?

Remediation is necessary due to the toxic nature of PCBs. PCBs can accumulate in the environment and in the tissues of living organisms, causing potential health and ecological risks. Moreover, they can migrate from soils into groundwater, contaminating aquifers and potentially entering the drinking water supply.

What are the methods of detecting Polychlorinated biphenyls (PCBs) in soils and aquifers?

Several methods exist for detecting PCBs, including gas chromatography-mass spectrometry (GC-MS), which is commonly used for analyzing soil and water samples. Emerging techniques, such as biosensors and immunoassays, offer quicker and potentially more cost-effective alternatives for field screening.

What techniques are used for Polychlorinated biphenyls (PCBs) remediation in soils?

Various techniques are employed, including physical methods like excavation and soil washing, chemical methods like solvent extraction and chemical oxidation, and biological methods like bioremediation. The choice of technique depends on several factors, including the type and level of contamination, soil properties, and cost considerations.

How are Polychlorinated biphenyls (PCBs) remediated in aquifers?

Remediation of PCBs in aquifers often involves methods such as pump-and-treat, permeable reactive barriers, and in situ chemical oxidation. These methods aim to either remove PCBs from the aquifer or transform them into less harmful compounds in place.

What is bioremediation and how is it used in Polychlorinated biphenyls (PCBs) cleanup?

Bioremediation involves the use of living organisms, usually microorganisms, to degrade or transform pollutants into less harmful forms. In the case of PCBs, certain bacteria and fungi have shown the ability to break down PCBs under suitable conditions. Bioremediation can be carried out either in situ or ex situ (in a controlled environment).

What is the role of technology in Polychlorinated biphenyls (PCBs) remediation?

Technology plays a crucial role in improving the efficiency and effectiveness of PCB remediation. Advances in biotechnology, nanotechnology, and materials science are leading to the development of novel remediation methods, such as engineered bio-agents, nanoscale zero-valent iron, and biochar-based sorbents.

What are some examples of successful Polychlorinated biphenyls (PCBs) remediation projects?

Successful remediation projects have been carried out worldwide, such as the dredging and capping of the Fox River in Wisconsin, the combined use of excavation, bioremediation, and thermal desorption at the Hunters Point Naval Shipyard in San Francisco, and the in situ treatment of a contaminated aquifer using a permeable reactive barrier in Australia.

What challenges are associated with Polychlorinated biphenyls (PCBs) remediation?

PCB remediation poses numerous challenges, including technical difficulties due to the physical and chemical properties of PCBs, high costs associated with large-scale cleanup operations, potential risks to human health and the environment during remediation, and regulatory complexities.

Read More