In structural engineering, the terms ‘tension-controlled’ and ‘compression-controlled’ refer to the failure modes of reinforced concrete (RC) beams. These failure modes are governed by the amount and configuration of the reinforcement provided in the RC sections. The control of failure modes in RC beams directly affects the structural safety, serviceability, and overall performance.

Structural engineering is replete with complex designs and methods, with tension-controlled and compression controlled beams being quintessential examples. It’s essential to comprehend the fundamental differences between these two variants, primarily the tension controlled beam and compression controlled beam, to enhance our understanding of structural engineering.

A tension controlled beam, as the name implies, primarily behaves under the influence of tension forces. The flexural strength of a tension-controlled concrete beam is determined by the tensile steel reaching its yield stress before concrete crushes. It’s crucial to understand that a tension controlled section’s ductility – its capacity to deform under stress without losing strength – is generally high, allowing for a more noticeable warning of failure. Hence, these types of beams are typically desired in seismic zones.

In contrast, a compression controlled beam behaves primarily under the influence of compression forces. The flexural strength of these beams is determined by the concrete reaching its ultimate compressive strength before the steel yields. Compression controlled sections tend to be less ductile and may experience a sudden failure, posing potential safety risks in seismic zones. Hence, they are typically employed in areas where the forces involved are predominantly compressive and less seismic activity.

The tension-controlled vs compression-controlled debate is fueled by the contrasting behaviors of these beams under stress. The tension and compression zones in a beam essentially refer to areas under tensile and compressive forces. The tension controlled and compression controlled beams typically exhibit different stress-strain behaviors, largely due to the inherent properties of concrete and steel used in their construction.

In a tension controlled concrete beam, for instance, the tension zone is predominantly handled by the steel reinforcement, since concrete is weak in tension. Here, the tension controlled section is designed to yield before the concrete fails in compression, providing the much-desired ductility.

On the other hand, a compression controlled section is predominantly made up of concrete, as it’s excellent in withstanding compression. The compression controlled zone is designed to fail when the concrete reaches its ultimate compressive strength, leading to a less ductile and potentially abrupt failure.

The dichotomy between tension controlled and compression controlled beams is stark, considering their behavior under different loads and their application areas. Their differences and usage will significantly influence the safety, resilience, and longevity of a structure. Whether choosing a tension controlled or compression controlled beam, an in-depth understanding of both is imperative for engineers to create sturdy, durable, and safe structures.

To sum up, the crucial difference between tension controlled and compression controlled beams is the former’s high ductility, which provides a clear warning before failure, while the latter’s low ductility could lead to abrupt failure. Also, the tension controlled section mainly comprises steel reinforcement due to its superior tensile strength, while the compression controlled section predominantly contains concrete, which has excellent compressive strength. The choice between tension and compression control depends on the specific load requirements and the nature of the environment where the structure is located.

Further, in this article the concepts of tension-controlled and compression-controlled beams, their features, design parameters, behavior under loads, and typical applications are discussed.

1.Defining Reinforced Concrete Beams

Before distinguishing between tension and compression-controlled beams, let’s understand the concept of a reinforced concrete beam. A RC beam is a structural element designed to resist loads primarily by bending.

It comprises concrete, which is strong in compression but weak in tension, and reinforcing steel, which has high tensile strength. The steel bars are embedded within the concrete to provide tensile strength, while the concrete offers the compressive strength, hence creating an efficient structural system.

2. Tension-Controlled Beams

In tension-controlled beams, the failure mode is predominantly governed by the yielding of the tension reinforcement, as opposed to the crushing of concrete in compression. These beams are generally characterized by large amounts of tensile reinforcement.

2.1 Design Parameters

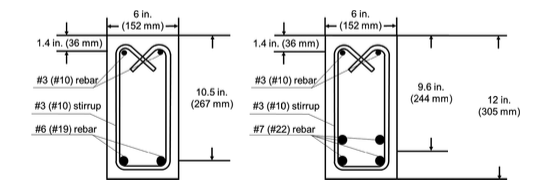

Design of tension-controlled beams is done based on the tension steel’s yielding strength. The strength reduction factor, typically denoted by Φ, is relatively high (0.90 according to the ACI Code). These beams are designed to have a smaller depth, leading to a reduced self-weight and economic use of materials.

2.2 Behavior under Load

Under loading, tension-controlled beams demonstrate large deformations before failure, providing ample warning signs. They exhibit a ductile behavior, meaning they can undergo significant deformation before failure. This allows for redistribution of stresses and is preferable in seismic areas, ensuring safety against sudden collapse.

2.3 Applications

Tension-controlled beams are usually deployed in seismic-prone regions due to their high ductility, and also in buildings and bridges where large deformations can be tolerated before failure.

3. Compression-Controlled Beams

Contrarily, in compression-controlled beams, the failure is primarily due to the crushing of concrete in the compression region before the yielding of tension steel. They are characterized by smaller amounts of tensile reinforcement.

3.1 Design Parameters

For compression-controlled sections, the strength reduction factor, Φ, is lower (around 0.65 according to the ACI Code). These beams are generally larger in size and require more material, contributing to increased self-weight.

3.2 Behavior under Load

These beams exhibit a brittle behavior, i.e., they can fail suddenly without much deformation or warning. The brittle failure is mainly because concrete, when subjected to excessive compression stress, fails abruptly without significant strain.

3.3 Applications

Compression-controlled beams are typically used in structures where ductility is not a major concern and where the design focuses on maximization of load-carrying capacity, like in industrial buildings or large spans.

Left is tension-controlled beam and right is compression-controlled beam.

4. The Balance: Transition Zone Beams

There exists a transitional zone between tension-controlled and compression-controlled beams, known as the ‘transition zone’ or ‘transition-controlled’ beams. These beams exhibit characteristics of both types, experiencing yielding of tension reinforcement and some concrete crushing at the time of failure. Designing a beam in this zone provides a balance between the ductility of tension-controlled beams and the load capacity of compression-controlled beams.

5. Classification of Beams as Per ACI 318

According to the ACI 318 code, the behavior of a section (tension-controlled, transition zone, or compression-controlled) is determined by the strain in the extreme tensile steel at nominal strength, denoted by εt.

- Tension-Controlled Sections: For a section to be tension-controlled, εt must be greater than or equal to εy (yield strain of the steel), which is typically 0.005 for Grade 60 steel. In tension-controlled sections, the steel yields before the concrete reaches its maximum strain, and failure is gradual with large deformations, which is a safer failure mode.

- Compression-Controlled Sections: For a section to be compression-controlled, εt must be less than 0.002. In these sections, the concrete in the compression region crushes before the steel yields. These sections exhibit brittle behavior, failing suddenly with little warning.

- Transition Zone: If εt is between 0.002 and εy (typically 0.005), the section is within the transition zone. The sections in this zone exhibit a combination of both behaviors. They experience some concrete crushing and some steel yielding at failure.

The numerical values mentioned above are critical in classifying the beam behavior. These values guide engineers in designing safe and efficient structures by helping them ensure that the failure mode of the beams is either tension-controlled or within the transition zone, thus avoiding a sudden, brittle failure.

6. Design Considerations

The American Concrete Institute (ACI) provides guidelines for designing RC beams. Per the ACI code, beams in buildings should be tension-controlled or at least fall within the transition zone to ensure ductile behavior. The strain in the extreme concrete compression fiber should not exceed a certain limit, preventing the beam from being compression-controlled and avoiding brittle failure.

7. Importance of Distinguishing

The distinction between tension-controlled and compression-controlled beams is vital for design considerations. A tension-controlled beam provides more deflection and warning before failure, ensuring better safety. On the other hand, a compression-controlled beam offers more load-carrying capacity but can fail suddenly. Therefore, understanding these classifications helps in choosing the correct beam type based on the structure’s requirements, be it ductility, load capacity, or deformation tolerance.

8. Structural Safety and Performance

Tension and compression-controlled beams represent two ends of the structural behavior spectrum. Tension-controlled beams, by providing ductile failure, can absorb energy and enhance the structure’s resilience, especially in seismic-prone areas. Compression-controlled beams, however, maximize the load-carrying capacity of a structure, which can be beneficial in specific design scenarios. The key lies in balancing the beam’s design to optimize both safety and performance, aligned with the building’s intended purpose and environmental conditions.

Differences Between Tension-Controlled and Compression-Controlled Beams as per the ACI 318

Following are the differences between tension-controlled and compression-controlled beams as per the ACI 318:

- Strain in Tensile Steel: For tension-controlled sections, the strain in the extreme tensile steel at nominal strength, εt, is greater than or equal to the yield strain of the steel, εy (typically 0.005). For compression-controlled sections, εt is less than 0.002.

- Failure Mode: Tension-controlled sections fail by yielding of the tension reinforcement, whereas compression-controlled sections fail due to the crushing of the concrete in the compression zone.

- Ductility: Tension-controlled sections demonstrate a high ductility due to yielding of steel before failure. In contrast, compression-controlled sections have low ductility, as the concrete crushes suddenly, leading to brittle failure.

- Strength Reduction Factor: The ACI Code specifies a strength reduction factor, Φ, of 0.90 for tension-controlled sections, whereas for compression-controlled sections, it is as low as 0.65.

- Deformations: Tension-controlled sections show large deformations before failure, providing a clear warning, while compression-controlled sections can fail suddenly with little to no warning.

- Safety: Tension-controlled sections are considered safer due to their ductile behavior and large deformations prior to failure, whereas compression-controlled sections pose a higher risk due to their sudden, brittle failure.

- Design Guidelines: ACI 318 recommends that sections in buildings should be tension-controlled or at least within the transition zone, but not compression-controlled, to prevent sudden, brittle failures.

- Seismic Performance: Tension-controlled sections are preferred in seismic-prone areas due to their high ductility and ability to absorb energy, while compression-controlled sections are not recommended due to their brittle behavior.

- Size and Material Usage: Tension-controlled sections can often be designed to have a smaller depth and less material, resulting in a lighter structure. Compression-controlled sections, however, tend to be larger in size, leading to increased self-weight.

- Load Capacity: While tension-controlled sections have a lower load capacity due to a focus on ductility, compression-controlled sections can have a higher load capacity as they utilize the compressive strength of concrete to the maximum before failing.

FAQ’s

What is a tension-controlled beam?

A tension-controlled beam refers to a type of reinforced concrete beam where the failure mode is primarily governed by the yielding of the tension reinforcement, instead of the crushing of the concrete in compression. These beams demonstrate ductile behavior, allowing significant deformation before failure.

How does a compression-controlled beam work?

A compression-controlled beam works primarily through the compressive strength of the concrete. The failure of this beam type occurs due to the crushing of concrete in the compression region before the tension reinforcement yields. They exhibit brittle behavior, meaning they can fail suddenly without much deformation.

Why do engineers use tension-controlled beams in seismic areas?

Engineers use tension-controlled beams in seismic areas due to their high ductility. These beams can undergo significant deformation before failure, which allows for the redistribution of stresses, ensuring safety against sudden collapse during seismic activities.

When are compression-controlled beams used?

Compression-controlled beams are used in structures where ductility is not a major concern, and the design focuses on the maximization of load-carrying capacity. Typical applications include industrial buildings or large spans where a sudden failure is less critical.

What is the difference between tension-controlled and compression-controlled beams?

The difference between tension-controlled and compression-controlled beams lies in their failure modes and behavior under load. Tension-controlled beams fail through the yielding of tension reinforcement and exhibit ductile behavior. In contrast, compression-controlled beams fail due to the crushing of concrete in compression, demonstrating brittle behavior.

How does the ACI code guide the design of tension and compression-controlled beams?

The American Concrete Institute (ACI) code provides guidelines for designing both tension and compression-controlled beams. It specifies a higher strength reduction factor for tension-controlled beams and a lower one for compression-controlled beams. Furthermore, it mandates that beams in buildings should be tension-controlled or at least fall within the transition zone to ensure ductile behavior.

What is the transition zone in beam design?

The transition zone refers to a state between tension-controlled and compression-controlled beams. Beams in this zone exhibit characteristics of both types, experiencing yielding of tension reinforcement and some concrete crushing at the time of failure.

Why is it important to distinguish between tension-controlled and compression-controlled beams?

It’s crucial to distinguish between these two types of beams as they have unique characteristics influencing their applications and the overall structural safety. Tension-controlled beams provide more deflection and warning before failure, ensuring safety, while compression-controlled beams offer more load-carrying capacity but can fail suddenly.

What is the structural behavior of tension and compression-controlled beams?

Tension-controlled beams demonstrate a ductile behavior, allowing significant deformation before failure. This behavior is desirable in seismic-prone areas. On the other hand, compression-controlled beams exhibit a brittle behavior, failing suddenly without much warning.

How do tension and compression-controlled beams affect the performance of a structure?

Tension-controlled beams can enhance the structure’s resilience by providing ductile failure and absorbing energy, especially in seismic-prone areas. Compression-controlled beams maximize the load-carrying capacity of a structure, beneficial in specific design scenarios. The key is to balance the beam’s design to optimize both safety and performance, aligned with the structure’s intended purpose and environmental conditions.

Read More

1 thought on “Top 10 Crucial Difference Between Tension-Controlled and Compression-Controlled Beams”