Strength design theory holds a critical position in the sphere of engineering, especially in domains such as civil, mechanical, and structural engineering. This groundbreaking concept has significantly transformed the landscape of engineering design, enabling engineers to design and evaluate structures with a renewed perspective. It encourages the creation of constructions that not only fulfill functional necessities but are also designed with a prime focus on endurance and safety. Structures born out of this innovative design theory exhibit a sophisticated balance of usability and robustness, marking a significant evolution in the realm of engineering.

Nevertheless, to fully appreciate the profound impact and the intricacies of strength design theory, one needs to delve into its foundational assumptions. These core principles provide the basis for the design approach and determine the strategies used in the development of safe and durable structures. In the forthcoming sections, this article aims to shed light on these fundamental principles. It seeks to provide an exhaustive understanding of the theory’s underpinnings, giving the reader a comprehensive insight into strength design theory.

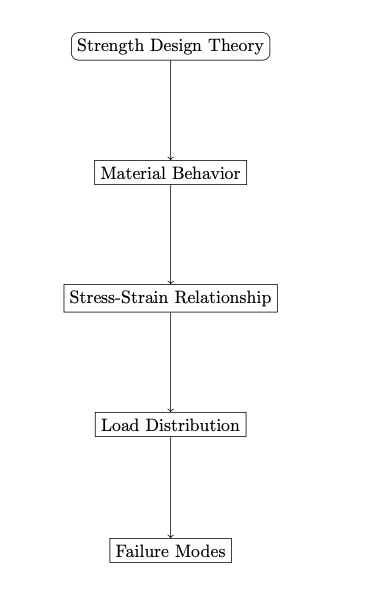

1.Definition of Strength Design Theory

Before delving into the assumptions of strength design theory, it’s essential to understand its definition and application. Strength design, also known as limit state design or ultimate load design, is a method that involves designing structures to withstand the maximum load they are expected to handle during their service life. This method is commonly used in the design of concrete structures, but its principles can be applied to other materials as well.

Strength design is centered around the concept of the ‘ultimate strength’—the maximum stress that a material or structure can withstand without failure. This is considered as opposed to ‘service load’ design, which considers only the regular, everyday loads that a structure will experience.

2. Basic Assumptions of Strength Design Theory

2.1 Material Behavior

2.1.1 Linear Elasticity

The first assumption of strength design theory relates to the behavior of materials. It’s assumed that materials behave elastically up to the point of yielding, following Hooke’s law, which states that strain is directly proportional to stress. This principle is known as linear elasticity. After reaching the yield point, however, materials are assumed to undergo plastic deformation.

2.1.2 Perfect Plasticity

Following the assumption of linear elasticity is the principle of perfect plasticity. This theory assumes that once a material surpasses its yield strength, it will continue to deform plastically without any increase in stress until it reaches its ultimate strength, at which point it will fail.

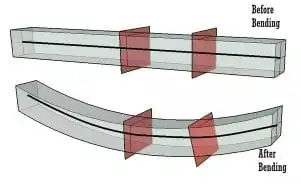

2.2 Stress-Strain Relationship

Another fundamental assumption of strength design theory is the stress-strain relationship of the material, which is often idealized for simplification. The theory assumes that the stress-strain curve is linear up to the elastic limit, after which it becomes perfectly plastic. This simplification enables the development of mathematical models for design purposes.

2.3 Load Distribution

The theory of strength design assumes that loads applied to a structure are distributed in a manner that allows the structure to utilize its full strength. This means that in the design phase, it is important to understand and consider how loads will be distributed across the structure.

2.4 Failure Modes

Strength design theory assumes that structures fail when their materials reach their ultimate strength. This is a simplification of the reality, where failure can occur due to a multitude of factors such as buckling, fatigue, and more. However, this assumption is made to facilitate calculations and develop a design that ensures the structure will not fail under its ultimate load.

2.5 Load Combination

The theory of strength design assumes that structures must withstand not just individual loads, but combinations of loads as well. Load combinations might include dead loads (permanent or static loads), live loads (transient or dynamic loads), and environmental loads (such as wind, earthquake, or snow). Engineers employ various combinations based on standard codes to ensure the structure’s safety under the most adverse conditions.

2.6 Structural Analysis

The theory of strength design assumes that the methods used for structural analysis accurately predict the behavior of a structure under load. Engineers often employ computer modeling and sophisticated mathematical techniques to analyze stress distribution, deformation, and other aspects of structural behavior. The accuracy of these models, however, relies heavily on the correctness of the assumptions about material properties and loading conditions.

2.7 Material Quality and Workmanship

The theory of strength design assumes that the quality of materials and workmanship complies with the standards specified in the design. The properties of the material, such as strength, ductility, and toughness, and the quality of construction, significantly influence the structure’s ability to resist loads. Poor material quality or construction errors can lead to premature failure, even if the design adheres to strength design theory.

3. Strength Design Theory in Practice

The use of strength design theory extends to a wide range of industries, from the design of bridges and buildings in civil engineering to the creation of machine components in mechanical engineering. Regardless of the application, the core assumptions remain the same, enabling engineers to create structures that can withstand ultimate loads while ensuring safety and efficiency.

4. Strength Design Theory: Beyond the Assumptions

While the assumptions of the theory of strength design form its foundation, it’s essential to remember that these are simplifications of complex real-world conditions. Hence, constant research and development are necessary to refine these assumptions and adapt them to evolving materials, technologies, and building techniques.

4.1 Continual Research and Development

Emerging technologies and advanced materials often require adjustments or additions to the basic assumptions of strength design theory. As we gain a better understanding of material behavior, load distribution, and structural analysis techniques, the theory evolves. Research and development efforts in this area ensure that strength design theory remains an effective tool for engineers around the world.

4.2 Application Across Industries

The principles and assumptions of strength design theory find application across various industries and engineering disciplines. In civil engineering, it’s used to design buildings, bridges, and other infrastructure. In mechanical engineering, it’s employed in the design of machine components and vehicles. And in aerospace engineering, it’s essential for creating aircraft and spacecraft structures.

4.3 The Future of Strength Design Theory

The future of strength design theory lies in its adaptability to the changing landscape of engineering. As the world grapples with challenges like climate change and urbanization, strength design theory will play a crucial role in creating resilient, sustainable, and efficient structures.

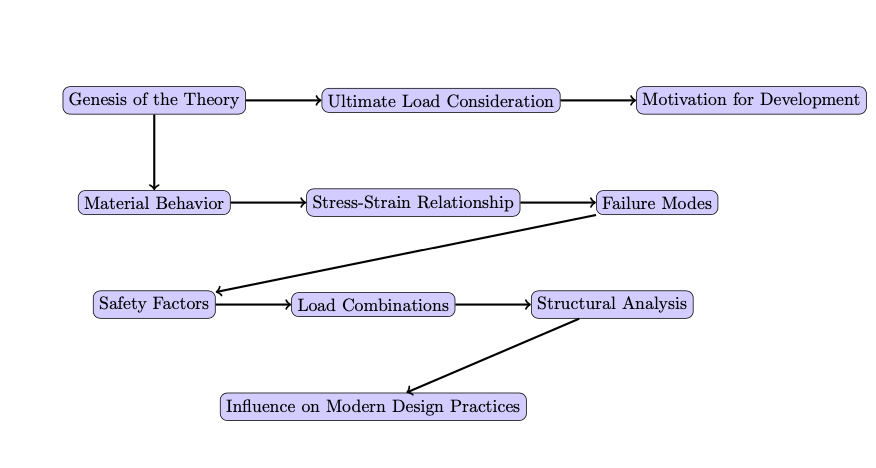

Evolution and Significance of Strength Design Theory

- Genesis of the Theory: Strength Design Theory, also known as Ultimate Load Design or Limit State Design, originated in the early 20th century. The need for a more accurate, safe, and comprehensive approach to designing structures led to the development of this theory.

- Ultimate Load Consideration: Unlike earlier design methods, which often considered only typical service loads, Strength Design Theory was developed to ensure structures could withstand their maximum expected loads, the “ultimate loads,” during their lifetimes. This was a significant step forward in terms of structural safety.

- Motivation for Development: The theory was primarily developed to overcome the limitations of earlier approaches, such as the working stress design method, which didn’t account for material behavior beyond the elastic limit. Strength Design Theory aimed to take into account the complete stress-strain curve of materials, right up to failure.

- Material Behavior: Strength Design Theory was one of the first design theories to assume that materials follow Hooke’s law up to their yield point, i.e., they behave elastically with stress being directly proportional to strain. After reaching the yield point, materials were assumed to undergo plastic deformation.

- Stress-Strain Relationship: One significant development in Strength Design Theory was the assumption that the stress-strain curve is linear up to the elastic limit, after which it becomes perfectly plastic. This simplification paved the way for the development of mathematical models for design purposes.

- Failure Modes: Strength Design Theory was developed with the belief that structures fail when their materials reach their ultimate strength. This marked a significant shift from previous design theories that didn’t consider structural behavior up to the point of failure.

- Safety Factors: The introduction of safety factors was a major development in Strength Design Theory. These factors were incorporated to act as a buffer against uncertainties in design, such as variations in material properties, load estimation errors, and unforeseen failure modes.

- Load Combinations: The concept of designing structures to withstand not just individual loads but combinations of loads was a critical advancement in Strength Design Theory. This approach ensures structures can handle a variety of load combinations, enhancing their safety and durability.

- Structural Analysis: The assumption that the methods used for structural analysis accurately predict the behavior of a structure under load was a significant innovation in Strength Design Theory. The development of computer modeling and sophisticated mathematical techniques greatly enhanced the accuracy of structural analysis.

- Influence on Modern Design Practices: The development of Strength Design Theory marked a turning point in engineering design practices. Today, this theory forms the foundation of various design codes and standards around the world, underscoring its importance in ensuring the safety, durability, and functionality of built structures.

FAQ’s

What is the Strength Design Theory?

Strength Design Theory, also known as Limit State Design or Ultimate Load Design, is a method of designing structures to withstand their maximum expected load during their service life. It revolves around the concept of ‘ultimate strength,’ the maximum stress a material or structure can endure without failure.

What are the basic assumptions of Strength Design Theory?

The fundamental assumptions of Strength Design Theory involve the behavior of materials, the stress-strain relationship, load distribution, and failure modes. It assumes materials follow Hooke’s law up to their yield point, stresses and strains have a linear relationship up to the elastic limit, loads are distributed to utilize full structural strength, and structures fail at their ultimate strength.

What is the role of safety factors in Strength Design Theory?

Safety factors in Strength Design Theory act as a buffer against uncertainties due to variations in material properties, load estimation errors, and unforeseen failure modes. They ensure structures can withstand loads beyond their design load, thus enhancing safety.

How is Strength Design Theory applied in practice?

Strength Design Theory is widely used in industries like civil engineering for designing bridges and buildings, and mechanical engineering for creating machine components. Regardless of its application, the core assumptions remain the same, providing a framework for engineers to create structures that can endure ultimate loads.

What are advanced considerations in Strength Design Theory?

Advanced considerations in Strength Design Theory include load combinations, structural analysis accuracy, and quality of materials and workmanship. Structures must withstand combinations of loads, structural analysis methods must predict actual structural behavior accurately, and materials and construction should comply with specified standards.

Why is continual research and development necessary in Strength Design Theory?

Ongoing research and development are crucial in Strength Design Theory to refine its assumptions and adapt to evolving materials, technologies, and building techniques. As we gain better insights into material behavior and structural analysis techniques, the theory continues to evolve.

What is the future of Strength Design Theory?

The future of Strength Design Theory lies in its adaptability to the changing engineering landscape. It will play a critical role in creating resilient, sustainable, and efficient structures to meet challenges like climate change and urbanization.

What industries use Strength Design Theory?

The principles and assumptions of Strength Design Theory are applied across various industries. Civil engineering uses it for designing infrastructure, mechanical engineering for machine components and vehicles, and aerospace engineering for aircraft and spacecraft structures.

How does Strength Design Theory contribute to sustainable structures?

By ensuring structures can withstand maximum stress without failure, Strength Design Theory contributes to sustainability. It leads to the design of resilient structures that can endure various loads over a long lifespan, reducing the need for frequent rebuilding or repair.

What is the relationship between Strength Design Theory and Hooke’s Law?

One of the basic assumptions of Strength Design Theory is that materials follow Hooke’s Law up to their yield point, behaving elastically with strain being directly proportional to stress. This is a key principle in understanding material behavior under load in Strength Design Theory.

Read More

2 thoughts on “Top-7 Basic Assumptions of the Strength Design Theory”