The iconic Willis Tower, formerly known as the Sears Tower, has been an architectural marvel since its completion in 1973, standing tall and proud in the heart of Chicago, Illinois. The structure, famous for its bold, tubular design and towering height, has drawn attention from architects, engineers, and admirers around the globe for its unique features and engineering brilliance. This article aims to present a comprehensive array of facts encompassing the extraordinary design, construction, and architectural elements that make Willis Tower an enduring symbol of human achievement.

Serving as an enduring testament to Chicago’s reputation as a hub for architectural innovation, the Willis Tower, spanning 110 stories into the city skyline, was designed by Bruce Graham and Fazlur Rahman Khan from the esteemed architectural firm Skidmore, Owings & Merrill (SOM). It was Khan’s revolutionary concept of the “bundled tube” structure that provided the Willis Tower with its distinct, robust form. This design not only enabled the building to achieve record-breaking height but also redefined the approach to skyscraper construction by providing greater stability, efficiency, and adaptability.

Despite losing its title as the world’s tallest building in 1998, the Willis Tower continues to be revered for its ingenious construction and design. With its caisson foundations burrowing 100 feet below ground, its structural system comprising of high-strength steel and reinforced concrete, and the carefully engineered load-distribution that enables it to withstand dynamic wind forces, the tower stands as a masterclass in architectural resilience.

The Willis Tower is more than just its impressive height and scale; it represents a fascinating confluence of architectural innovation, engineering prowess, and economic pragmatism. The tower’s bundled tube design, for instance, reduced the amount of steel required by 50%, representing not just a structural, but also an economic advantage. In addition, the tower has undergone several renovations to improve its energy efficiency, achieving LEED Gold certification for its sustainability efforts.

However, the Willis Tower is not just about its structure and efficiency. The tower, as a complete entity, has many features that make it remarkable. From the high-speed elevators and expansive Skydeck offering panoramic views of Chicago to the 16,100 bronze-tinted windows that give the building its distinctive look, every detail of the Willis Tower has been designed with precision and purpose.

Moreover, the Willis Tower is a testament to the importance of considering the building’s interaction with the natural environment. It is designed to sway gently in response to high winds, an essential attribute given Chicago’s moniker as “The Windy City”. At the same time, its modern upgrades have focused on enhancing energy efficiency, contributing to urban sustainability goals.

Over the decades, the Willis Tower has garnered a reputation that extends beyond the architectural and engineering communities. It’s a popular tourist attraction, with its Skydeck drawing more than 1.7 million visitors each year. Additionally, it’s a significant commercial hub, housing more than 300 companies and providing an economic boost to the city of Chicago.

This article presents an in-depth exploration of the Willis Tower’s top 100 construction and design facts. The goal is to shed light on the intricate details that contribute to the tower’s grandeur, the technical aspects that underpin its construction, and the intriguing stories that add to its legacy. This comprehensive compilation is aimed not just at architects, engineers, and students but also at anyone interested in understanding the marvels of human ingenuity and the limitless possibilities of architectural design. Each fact is a testament to the foresight, creativity, and technical expertise that went into creating the Willis Tower – a timeless beacon of architectural brilliance in the heart of Chicago.

Top-100 Facts of Willis Tower Chicago

- The Willis Tower, originally known as the Sears Tower, is one of the most iconic skyscrapers in the world and is located in Chicago, Illinois.

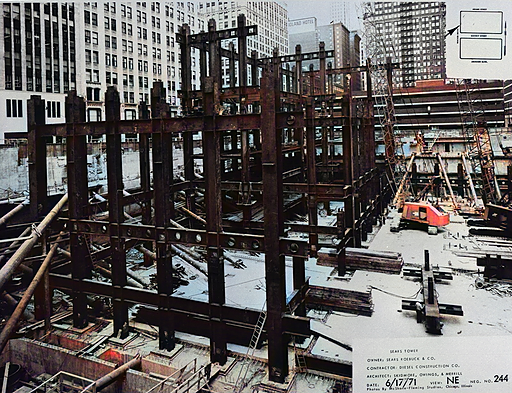

- Its construction began in August 1970 and was completed in September 1973.

- The official name was changed to Willis Tower in 2009 when the London-based insurance broker Willis Group Holdings leased a portion of the building and obtained the building’s naming rights.

- The project was commissioned by Sears, Roebuck & Co. to house its rapidly growing staff.

- The tower was designed by architect Bruce Graham and structural engineer Fazlur Rahman Khan from the architectural firm Skidmore, Owings & Merrill (SOM).

- Fazlur Rahman Khan is known for his innovations in structural design, especially the tube structure concept, which was first applied in the Willis Tower.

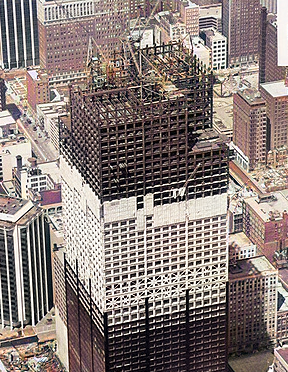

- The Willis Tower’s design incorporates nine square “tubes” in a 3-tube by 3-tube configuration, creating a unique stepped design.

- This ‘bundled tube’ design provides greater structural stability and allows for large open floor spaces without the need for interior columns.

- This design not only supports the building’s weight but also helps resist lateral forces from wind and potential earthquakes.

- The total cost of construction was approximately $175 million, which, adjusted for inflation, would be around $1 billion today.

- The Willis Tower measures 1,450 feet (443.2 meters) tall. Including its antenna, the total height is 1,729 feet (527 meters).

- The tower consists of 110 floors, primarily composed of office and retail space.

- A skydeck is located on the 103rd floor, offering visitors a panoramic view of the city.

- Its foundation type is caisson foundations.

- The depth of the foundation reaches up to 100 feet (30.5 meters) below the ground.

- The structure is primarily composed of structural steel and reinforced concrete.

- An estimated 76,000 tons of steel were used in the construction of the tower.

- The exterior of the building is made of anodized aluminum.

- To construct the foundation, the builders used caissons that extended through 100 feet of soil and clay, then down to bedrock.

- The high-strength structural steel used in its construction was developed specifically for the tower.

- Over 2 million cubic feet of concrete was used in the building’s construction, enough to build an eight-lane, five-mile-long highway.

- The tower’s window washing system is a unique design, as the windows cannot be cleaned from the ground due to their height.

- It takes approximately six weeks to clean all of the tower’s windows.

- The tower has 16,100 bronze-tinted windows.

- The building has a total floor area of 4.5 million square feet (418,064 square meters).

- The building’s bundled tube design was recognized as a significant architectural and engineering accomplishment, serving as a model for future skyscrapers.

- The building was designed according to the 1969 Chicago Building Code.

- The elevators in the tower can travel at speeds of 1,600 feet per minute, making them some of the fastest in the world.

- During construction, more than 2,000 workers were on site every day.

- The building is designed to sway in response to the wind; on a typical day, it may sway 3 to 6 inches, but it can sway up to 12 inches in high winds.

- The building’s cladding was designed to reflect the sky, allowing it to blend into the Chicago skyline.

- Despite its height, the Willis Tower only has two basement levels.

- The design of the Willis Tower includes various safety features, such as reinforced concrete cores that provide additional strength and fire resistance.

- The steel used in the tower’s construction had a yield strength of 50,000 psi, and the concrete used was rated at 6,000 psi.

- At the time of its completion, the Willis Tower was the tallest building in the world, a title it held for 25 years until it was surpassed by the Petronas Towers in Kuala Lumpur, Malaysia, in 1998.

- The Willis Tower’s skydeck attracts more than 1.7 million visitors each year.

- To stabilize the structure, outrigger trusses are used, which are located between the central core and the perimeter columns.

- It is estimated that the life span of the building can be over 100 years with appropriate maintenance and renovations.

- The site’s soil is made up of dolomite, a sedimentary carbonate rock, and silty clay loam, which is a common soil type in Chicago.

- It is estimated that the Willis Tower weighs about 222,500 tons.

- The building uses an active tuned mass damper system to counteract swaying.

- The original interior design of the tower was influenced by the 1970s aesthetics, with a lot of dark woods and natural stone.

- The Willis Tower is also designed to support a number of radio and television broadcasts with its towering antennae.

- After the attacks on the World Trade Center on September 11, 2001, the tower’s security was significantly increased.

- The Willis Tower is energy-efficient and was awarded the Energy Star Label in 2018.

- In 2009, a $350 million green renovation project was initiated to improve the tower’s energy efficiency.

- This renovation included the replacement of all 16,100 windows with high-performance glazing.

- The HVAC system was also upgraded, and the lighting was replaced with more energy-efficient options.

- The roof of the tower is covered with a white reflective material to reduce the heat island effect.

- In 2018, the Willis Tower achieved LEED Gold certification for its sustainability efforts.

- The tower’s structural system provides an excellent example of the economic efficiency of the tubular system, as it uses less steel than a traditional design for a building of the same height.

- The economic analysis of the structure shows that its innovative design resulted in significant cost savings during construction and continues to provide benefits in terms of energy efficiency and maintenance costs.

- The Willis Tower is home to more than 300 companies, including prominent firms like United Airlines and law firm Schiff Hardin.

- The tower includes amenities such as a fitness center, conference facilities, and a variety of dining options.

- The Skydeck underwent a renovation in 2020, adding new features like a glass ledge that allows visitors to step out over the city below.

- The tower’s lobby was redesigned in 2017, providing a more open and modern entrance to the building.

- The Willis Tower is a popular film location and has appeared in numerous movies and TV shows.

- The tower is an integral part of Chicago’s skyline and is often lit up for special occasions

- Despite its official name change in 2009, many Chicagoans still refer to the building as the Sears Tower.

- The tower’s antennae are important for broadcasting and telecommunications throughout the Chicago metropolitan area.

- With its innovative construction techniques and the use of modern materials, the Willis Tower was a breakthrough in skyscraper design.

- Even though it’s no longer the world’s tallest building, the Willis Tower remains a prominent symbol of Chicago’s architectural heritage.

- In terms of combined base, antenna, and structural height, the Willis Tower was surpassed by the One World Trade Center in New York City.

- It was the first building to use Khan’s bundled tube structure, revolutionizing the design of tall buildings.

- A helicopter was used to install the two television antennae.

- The tower’s highest occupied floor is level 104.

- When the tower was constructed, the architects considered potential challenges from earthquakes and high wind loads.

- The Willis Tower contains enough telephone cable to wrap around the Earth nearly 1.5 times.

- Around 25,000 people work in the Willis Tower daily.

- It has approximately 16,100 bronze-tinted windows, which gives the building its iconic dark look.

- The bundled tube design of the tower reduces the amount of steel required for a high-rise building of a similar height by 50%.

- The tower was built with 76,000 tons of structural steel and 2 million cubic feet of concrete.

- The tower has 104 elevators, including 16 double-deck elevators.

- It was constructed using bolted connections, which was a significant innovation at the time of its construction.

- The Willis Tower’s structural system is designed to be highly redundant and capable of transferring loads between different parts of the structure in the event of a failure.

- As a result of its innovative design, the Willis Tower has been able to accommodate changes in use and modifications over its lifespan without major structural alterations.

- Despite its impressive height, the tower only requires five main hoisting and utility elevators.

- The tower’s maintenance crew includes two full-time electricians and two full-time plumbers.

- The tower has been a part of numerous high-profile events, including charity stair-climbing races.

- Its Skydeck, with a glass-bottomed ledge, gives visitors a vertigo-inducing view 1,353 feet straight down.

- The Willis Tower was one of the last skyscrapers built in the US before the 1973 oil crisis led to a slowdown in skyscraper construction.

- The soil at the site of the tower was examined using borings and laboratory tests to determine its composition and properties.

- In 1982, a record was set when two television antennas were added, bringing its total height to 1,729 feet.

- It was designated a city landmark in 2013 by the Commission on Chicago Landmarks.

- The tower’s Skydeck competes with the Hancock building’s observatory, which also offers panoramic views of the city and Lake Michigan.

- The tower’s economic impact on the city of Chicago is significant, providing jobs, attracting tourists, and offering retail spaces.

- The tower was built to withstand the harsh weather conditions of Chicago, known as “The Windy City.”

- A special damping system is used in the tower to reduce the amount of sway experienced by occupants.

- The Willis Tower was one of the first structures to use a ‘skylobby,’ an intermediate floor where people can change from an express elevator to a local elevator.

- The tower’s plaza on the west side of the building includes a sculpture entitled “Universe” by Alexander Calder.

- In terms of sustainability, the tower has reduced its electricity usage by 34% since the 1980s.

- The Willis Tower uses a high-efficiency water-cooling system for air conditioning.

- The Willis Tower’s Skydeck can be seen from four different states: Illinois, Indiana, Wisconsin, and Michigan.

- The building has a volume of 37 million cubic feet.

- The tower’s two antennas are illuminated at night and change color for various events and holidays.

- The Willis Tower’s design was innovative for its time and has influenced the design of many subsequent high-rise buildings worldwide.

- The tower can withstand wind loads of up to 55 pounds per square foot.

- Willis Tower was the first building to surpass the height of the north tower of the World Trade Center in New York.

- There are approximately 25,000 sprinkler heads in the Willis Tower, which contribute to the fire safety of the building.

- The Willis Tower’s iconic status has led to its inclusion in numerous works of popular culture, including films, television shows, and video games.

FAQ’s

What is the Willis Tower made of?

The Willis Tower, previously known as the Sears Tower, is primarily made of high-strength structural steel, reinforced concrete, and black anodized aluminum. The building’s innovative bundled tube design allowed the reduction of steel usage by about 50% compared to skyscrapers of similar height.

Who designed the Willis Tower?

The Willis Tower was designed by architect Bruce Graham and structural engineer Fazlur Rahman Khan of the architectural firm Skidmore, Owings & Merrill.

How long did it take to build the Willis Tower?

The construction of Willis Tower started in August 1970 and was completed in September 1973. So, it took approximately three years to build.

How tall is the Willis Tower in Chicago?

The Willis Tower stands at a height of 1,450 feet (442.1 meters) to the roof. Including its antenna towers, the total height is 1,729 feet (527 meters).

What type of foundation does the Willis Tower have?

The Willis Tower utilizes deep caisson foundations. These caissons reach depths of approximately 100 feet below the ground level, allowing the skyscraper to stand firm by resting on the sturdy rock layer beneath.

What type of loading does the Willis Tower withstand?

The Willis Tower is designed to withstand different types of loads, including gravity loads (self-weight and occupancy loads), wind loads, and dynamic loads. The bundled tube design of the structure helps distribute these loads effectively.

What is the bundled tube design of the Willis Tower?

The bundled tube design of Willis Tower is a revolutionary architectural concept that was first implemented in its construction. The tower is composed of nine square tubes in a 3×3 grid at the base, each essentially acting as a separate building. The bundles stop at varying heights, giving the tower its unique, staggered appearance.

How many floors does the Willis Tower have?

The Willis Tower has a total of 110 floors. This includes office and retail spaces, as well as the famous Skydeck located on the 103rd floor.

How much did it cost to build the Willis Tower?

The total cost of constructing the Willis Tower was about $150 million in 1973. Adjusted for inflation, this amount is equivalent to roughly $800 million today.

What materials were used in the construction of the Willis Tower?

The primary materials used in the construction of the Willis Tower were structural steel and reinforced concrete. Approximately 76,000 tons of steel and 2 million cubic feet of concrete were used. The exterior is clad in black anodized aluminum and bronze-tinted glass, giving the building its distinctive dark appearance.

Read More

1 thought on “Willis Tower Chicago : Top-100 Construction and Design Facts”